Page 447 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 447

Process Safety and Pressure-Relieving Devices 413

FEATURES:

• Isolates Safety Relief Valves

• No Fragmentation

• Operates up to 90% Rated

Pressure

• Can Withstand Full Vacuum

without Supports

• Available in Sizes 1" thru 36"

• Wide Material Availability

• U.S. Patent Number

3,294,277

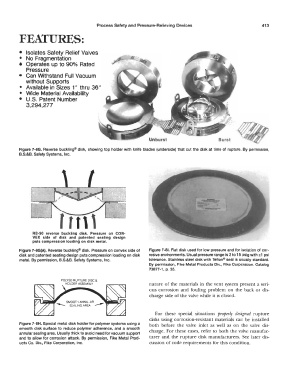

Unburst Burst

Figure 7-SG. Reverse buckling® disk, showing top holder with knife blades (underside) that cut the disk at time of rupture. By permission,

B.S.&B. Safety Systems, Inc.

RB-90 reverse buckling disk. Pressure on CON-

VEX side of disk and patented seating design

puts compression loading on disk metal.

Figure 7-8G(A). Reverse buckling® disk. Pressure on convex side of Figure 7-81. Flat disk used for low pressure and for isolation of cor-

disk and patented seating design puts compression loading on disk rosive environments. Usual pressure range is 2 to 15 psig with ± 1 psi

metal. By permission, B.S.&B. Safety Systems, Inc. tolerance. Stainless steel disk with Teflon® seal is usually standard.

By permission, Fike Metal Products Div., Fike Corporation. Catalog

73877-1, p. 35.

nature of the materials in the vent system present a seri-

ous corrosion and fouling problem on the back or dis-

charge side of the valve while it is closed.

For these special situations properly designed rupture

disks using corrosion-resistant materials can be installed

Figure 7-SH. Special metal disk holder for polymer systems using a both before the valve inlet as well as on the valve dis-

smooth disk surface to reduce polymer adherence, and a smooth charge. For these cases, refer to both the valve manufac-

annular sealing area. Usually thick to avoid need for vacuum support

and to allow for corrosion attack. By permission, Fike Metal Prod- turer and the rupture disk manufacturers. See later dis-

ucts Co. Div., Fike Corporation, Inc. cussion of code requirements for this condition.