Page 502 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 502

468 Applied Process Design for Chemical and Petrochemical Plants

Table 7-13

Convenient Pressure Conversions

Oz./in. 2 Lb./in. 2 In. Hg (0°C) In. H 2 0 (4°C)

1 0.06250 0.1272513 1.730042

e 16 2.036021 27.68068

7.85846 0.4911541 1 13.59548

0.57802 0.0361262 0.07355387

can significantly influence the safety relieving require-

ments. Usually, these are [26]

1. Normal operation

(a) Outbreathing or pressure relief

(b) Inbreathing or vacuum relief

2. Emergency conditions

(a) Pressure venting

3. For tank design per API Standard 650 with weak roof

to shell designs (roof lifts up) the venting require-

ments of API-Std-2000 do not apply for emergency

venting to atmosphere or elsewhere.

Nonrefrigerated Above Ground Tanks; API-Std. 2000

Normal operations are to be established within the

design parameters for the tank, thereby avoiding condi-

tions that would damage it. Normal venting capacity

should be at least the sum of venting required for oil/flu-

ids movement and thermal effect. Required capacity can

be reduced when liquid volatility is such that vapor gen-

eration or condensation in the allowable operating range

of vessel pressure will provide all or part of the venting

requirements.

--G-

Outbreathing conditions are usually established when (a)

the tank is being filled and the vapor space is being dis-

placed with liquid, (b) thermal expansion and evapora-

tion of the liquid, and (c) external fire on the vessel cre-

ating additional heat input to the contents.

The standard [26] specifies venting capacity of:

I. Twelve hundred cubic foot of free air per hour for

every 100 barrels ( 4200 gal) per hour of maximum

filling rate, for liquids with flash points below l00°F.

2. Six hundred cubic foot of free air per hour for each

100 barrels ( 4200 gal) per hour of maximum filling

rate, for liquids with flash points 100° F. and above.

3. Thermal outbreathing or venting requirements,

including thermal evaporation for a fluid ( the code

refers to oil) with a flash point of 100°F or below, use

at least the figures of Column 4 in Table 7-14.

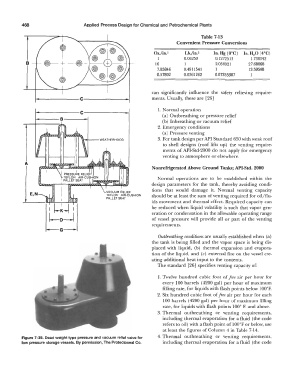

Figure 7-35. Dead weight type pressure and vacuum relief valve for 4. Thermal outbreathing or venting requirements,

low pressure storage vessels. By permission, The Protectoseal Co. including thermal evaporation for a fluid (the code