Page 501 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 501

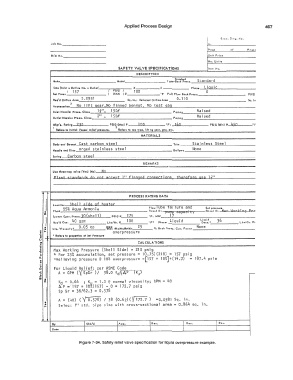

Applied Process Design 467

Spec, DwQ, No.

Job No, A·

Po ge of

8/M Na, _ Unit Priee

No. Unih

c= SAFETY VALVE SPECIFICATIONS Item No.

DESCRIPTION

�

�

r::--==============·=========-M_o_d_o= I -= --------=====_= =T=y=p- • ·"!'t- , ." P-,:i_ - . -==S=t=a=n=d=a==rd================---

��� � ••

Sise (Inlet• Odflco No, • Outlet) x x Phose Llguid

i 157 ( PSIG ) 100 0

Set Pres, ( xxx )@ OF Full Flow Back Pren, PSIG

0.0951 0.110

Req'd Orlflco Area Sq, In,; Salec1ed Orifice Area So, In

2

AcC'•••orles No ii ft gear,No finned bonnet, Mo test gag

2

Inlet Nozzle: Pren, Clau 1 "' • 150# F aclnq Raised

2" , 150# Raised

Outlet Nozzle1 Pieu, Closs Facln9

Miii''•• Rating 230 PSIG (Max)@ 100 OF: 160 PSIG (Min)@ !!50 .,

1 2

Refers to lnl�al Veasel reliaf pressure, Ref•rs to cop type, lifting gear, gag, etc,

MATERIALS

Body and Bonnet Ca�t csirbQD 2t!il�l Trim Stainless Steel

orged stainless steel None

Nozzle ond Disc Befl ew s

Spring r;i,-hnn <: �001

REMARKS

U•• th, ... way �Ive (Yesj (No) tfo

..eJ..ant stacdacds dc_nat accept ]" flanged ccaaecticas, tberefore use ]!"

PROCESS RATING DATA

I Loco ti on 95% Aqua Ammonia Flow I Ube fa1 lure ana Set prossure

Shel! sjde Qf heater

Fluid

0

z Sy1t.m o.,.,. Prou. 30 ( she I I) PSIG@ 275 Based On ptll7 eapaeit, Ba sod On ...M,a}( \Jack 1 og Pr.c

°掩ȈF: MW·

. I Req'd Cap. 40 gpm Lba/Hr,@ 100 25 • F* %: Bade Prd>ss. Corr. Factor None 36 L i»/Cu. Ft

Liquid

liquid

Phu,e:

Oen•.•

• .

0.05 cp

overpressure

•

a. )- Liq. Vf•C'O•ity• 1� Al:c�tllln

• Rofer1 to propertio• at Set Pressure

..

0

.

u CAL CULA Tl ONS

c

0

� . Max �lork i ng Pressure (Shell Side) = 210 psig

... * For 25% accumulation, set pressure= (0.75)(210) = 157 psi g

c ·"Re 1 i ev i ng pressure@ 10% overpressure =[157 + 10%]+(14;1) = 187.4 psi a

0

•

0 For Liquid Relief: per ASME Code

"" u 0 I A = GPM ( � SpGr )/ 38,o Kd�AP (Ku) -

iii

I • z Kd = o.64 ; K = 1.0@ normal viscosity; GPM = 40

�

AP ='157 + 100(157) - 0 = 172.7 psig

I Sp Gr = 36/62,3 = 0.578

• • I A = (40) ( \/ 0.578) I 38 (0.62) ( yT-iG ) =0.0981 Sq. In. in.

o.864 sq.

)- Select 1" std. pipe size with cross-sectional area =

l

Sy I Chk'd JApp, I Rev, J Rev, J Rev,

Date I I I I I

Figure 7-34. Safety relief valve specification for liquid overpressure example.