Page 498 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 498

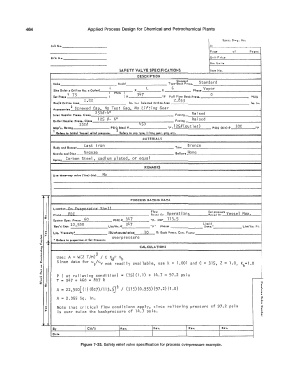

464 Applied Process Design for Chemical and Petrochemical Plants

I'- Spec. Dwq, No.

Job No.. _ ------

� of Po ;es

Pa qe

B/M No. Unit Price

No. Unih

SAFETY VALVE SPECIFICATIONS Item No.

DESCRIPTION

Standard Stamdard

Mako Modol Type•Back Press.

If L 6 Vapor

Size (Inlet x Oriflee No, x Outlet) ( x x Phose

�

1 75 PSIG ) 3 1 7 0

Set Pres, ( )@ 'F Full Flow Back Pross. PSIG

2.02 ?..853

Req'd Orifice Area Sq. In.: Selected Orifice Area Sq, In,

2 Screwed Cao. No Test Gaq No Liftinq Gear

Acce1aorfe1

250#-4" Raised

Inlet Nozzle: Pr•••· Clau Facin;

125 #- 6" Raised

Outlet Nonie: Preu, Clou Facing

250# 450

Mfgr'1, Roting PSIG (Mox)<. , �, 1 2 5# ( OU t 1 et) PSIG (M;n)@ 300 'F

1 2

Ref.,, to lnltfal Ve11el relief pressure. Refers to cop type, lifting gaar, gag, otc:.

MATERIALS

Cast Iron Bronze

Body and Bonnet Trim

9ronze Bellows None

Nonie and Dl1c

Carbon Stee 1, cadium plated, or equal

Spring

REMARKS

Uoo throo•way wive (YH) (No) No

PROCESS RATING DATA

I Location n ..... �"".'11,--,...�t,,....,..,. C"L.-11 Flow tt.::to � ure

• Fluid PDC Basad On Operations Vesse 1 Max.

z SyaNm Oper. Pr•••· 60 PSIG@ 347 'F: MW• 113.5

. I RM'd Cop, 22, 500 Lbs/Hr,@ 347 'F* Phase: Liquid Lbs/Cu. Ft,

Dens.•

• • . ,... Liq, Vi1co1ity* SSU :XA«u..i, lc,tiol( ]Q %: Back Pren. Corr. Factor

overpressure

...

. -

..

• R•fen to properties at S.t Prea1ure

.

u CALCULATIONS

�

..c a '

I

� � Use: A= W(Z T/M)i c KdP Kb

� Since data for c/cv not readily available, use k = 1.001 and c = 315, z = 1.0, Kb=l ,0

0

�

0

.,, p ( at relieving condition) = (75)(1.1) + 14.7 = 97.2 psi a --

• I T = 347 + 460 = 807 R

u

iii 0 "ti

z � ,,.

A = 22, 500[ ( 1) ( 807) I 113. 5] t I (315) (0.953) (97,2) (1.0) .

0

. I A = 2.055 Sq. In, �

?

�

• ,... Note that critical flow conditions apply, since relieving pressure of 97.2 psi a z

is over twice the backpressure of 14.7 psi a. 3 <T

=

--

By I Chk'd I App. I Rev. 1 Rev, J Rev,

Dot• I I I I l

Figure 7-33. Safety relief valve specification for process overpressure example.