Page 75 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 75

Fluid Flow 59

Usual Industry Pipe Sizes and Classes Practice the corrosion rate over a five-year life required 0.125

in. (Ys in.), then the 0.200 in. + 0.125 in. = 0.325 in.

Certain nominal process and utility pipe sizes are and the Schedule 40 pipe would not be strong enough

not in common use and hence their availability is lim- at the end of five years. Often the corrosion is calcu-

ited. Those not usually used are: % in., lX in., 2� in., 3X lated for 10- or 15-years' life before replacement. Cur-

in., 5 in., 22 in., 26 in., 32 in., 34 in. rently Schedule 80, 3-in. pipe has a 0.300 in. wall

Some of the larger sizes, 22 in. and up, are used for spe- thickness, so even this is not good enough in carbon

cial situations. Also, some of the non-standard process steel. Rather than use the much heavier Schedule 160,

sizes such as 2x; in., 3% in. and 5 in. are used by "packaged" the designer should reconsider the materials of con-

equipment suppliers to connect components in their sys- struction as well as re-examine the corrosion data to

tem for use in processes such as refrigeration, drying, or be certain there is not unreasonable conservatism.

contacting. Perhaps stainless steel pipe or a "lined" pipe would

The most common schedule in use is 40, and it is use- give adequate strength and corrosion resistance. For a

ful for a wide range of pressures defined by ANSI Std. B bad corrosion condition, lined pipe using linings of

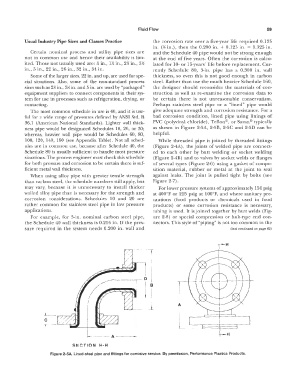

36. l (American National Standards). Lighter wall thick- PVC (polyvinyl chloride), Teflon®, or Saran® typically

ness pipe would be designated Schedules 10, 20, or 30; as shown in Figure 2-5A, 2-5B, 2-5C and 2-50 can be

whereas, heavier wall pipe would be Schedules 60, 80, helpful.

100, 120, 140, 160 (see Appendix Table). Not all sched- While threaded pipe is joined by threaded fittings

ules are in common use, because after Schedule 40, the (Figure 2-4A), the joints of welded pipe are connect-

Schedule 80 is usually sufficient to handle most pressure ed to each other by butt welding or socket welding

situations. The process engineer must check this schedule (Figure 2-4B) and to valves by socket welds or flanges

for both pressure and corrosion to be certain there is suf- of several types (Figure 2-6) using a gasket of compo-

ficient metal wall thickness. sition material, rubber or metal at the joint to seal

'When using alloy pipe with greater tensile strength against leaks. The joint is pulled tight by bolts (see

than carbon steel, the schedule numbers still apply, but Figure 2-7).

may vary, because it is unnecessary to install thicker For lower pressure systems of approximately 150 psig

walled alloy pipe than is necessary for the strength and at 400°F or 225 psig at l00°F, and where sanitary pre-

corrosion considerations. Schedules 10 and 20 are cautions (food products or chemicals used in food

rather common for stainless steel pipe in low pressure products) or some corrosion resistance is necessary,

applications. tubing is used. It is joined together by butt welds (Fig-

For example, for 3-in. nominal carbon steel pipe, ure 2-8) or special compression or hub-type end con-

the Schedule 40 wall thickness is 0.216 in. If the pres- nectors. This style of "piping" is not too common in the

sure required in the system needs 0.200 in. wall and (text continued on page 62)

H

B 1

I

I

I

A

L-��--,--, I

c L

T -

SECTION H-H

Figure 2-5A. Lined-steel pipe and fittings for corrosive service. By permission, Performance Plastics Products.