Page 76 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 76

60 Applied Process Design for Chemical and Petrochemical Plants

1 • · 5· SCH 80

a· · SCH 40

PIPE

FLANGE 2

\ \ PFA LINED

& JACKETED

i

A= LENGTH --- _J

MAX 120"

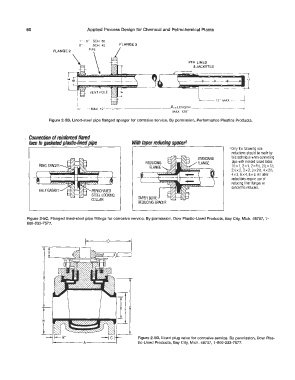

Figure 2-58. Lined-steel pipe flanged sparger for corrosive service. By permission, Performance Plastics Products.

Connection of reinfon:ed flared

face to gasketed plastic-lined pipe With taper reducing spacer2

2 Only the following size

reductions should be made by

lhis technique when connecting

pipe with molded raised faces:

1Yix1, 2x1. 2x1Yi, 2Yix1Y1,

2Yix2, 3x2, 3x2Yi, 4x2Yi,

4 x 3, 6x 4, 8 x6. All other

reductions require use al

reducing filler llanges or

concentric reducers.

TAPER BORE

REDUCING SPACER

Figure 2-5C. Flanged lined-steel pipe fittings for corrosive service. By permission, Dow Plastic-Lined Products, Bay City, Mich. 48707, 1-

800-233-7577.

Figure 2-50. Lined plug valve for corrosive service. By permission, Dow Plas-

tic-Lined Products, Bay City, Mich. 48707, 1-800-233-7577.