Page 130 - Module DMV20173

P. 130

6.0 POLYMER PROCESSING

panels for shower stalls, and packaging.

Figure 6.15 Various thermoforming processes for a thermoplastic sheet.

7.7.1 PROCESS CAPABILITIES

1. Typical parts made by thermoforming are packaging, trays for cookies and candy,

advertising signs, refrigerator liners, appliance housings, and panels for shower stalls.

2. Molds for thermoforming usually are made of aluminum because high strength is not

required, hence tooling is relatively inexpensive.

3. Quality considerations include tearing of the sheet during forming, nonuniform wall

thickness, improperly filled molds, poor part definition, and lack of surface details. Figure

6.16 shows the production line for thermoforming process.

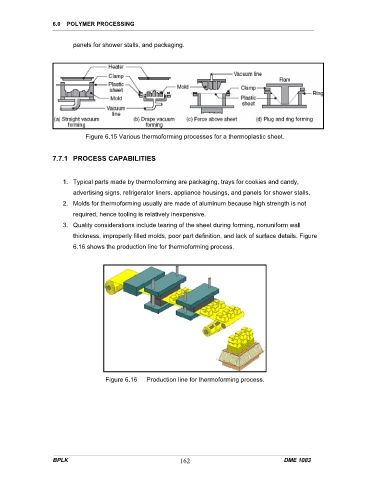

Figure 6.16 Production line for thermoforming process.

BPLK 162 DME 1083