Page 38 - 2010-2022 hose manufactureing ability and guide

P. 38

Of the three flexible mandrel styles, solid Manufacturing with rigid mandrels offers

rubber offers minimal support, while rubber two unique production opportunities. Rigid

with wire core and thermoplastic versions mandrels can be (1) rotated on a stationary

provide good dimensional control. In all cases, horizontal axis, similar to a lathe, so that

the flexible mandrel is removed from the hose material can be applied in bias style or (2) fed

with either hydrostatic pressure or mechanical horizontally through the tubing, reinforcing and

push/pull after processing. The mandrel is then covering operations as the various hose

inspected for dimensional and cosmetic components are spirally fed onto the mandrel.

imperfections, rejoined into a continuous length, The former method is often referred to as Hand

and recycled into the hose making process. Built hose. The reference of Wrapped Ply hose

Although the flexible mandrel is continuous, can be associated with either method. Some

limitations of expulsion from the finished hose hand built hoses, depending on the application,

rarely allow hose lengths above 1000 ft. Either have special ends to accommodate its

textile or wire reinforcements may be used. attachment to existing flanges in the field.

Examples of this style product are power Figure 2-1 shows a 6-ply wrapped hose.

steering, hydraulic, wire braided and air One traditional method of making wrapped

conditioning hoses.

ply hose is on a three roll builder. This machine

Rigid Mandrel Style consists of three long steel rolls, two of which

are in a fixed parallel position in the same

In larger hose sizes, where flexible mandrels

become quite cumbersome to handle, working horizontal plane.

pressures are high, or stringent dimensional The third or top roll is on pivotal mounts so

control is required, the rigid mandrel process is that it can be raised or lowered. A mandrel

the preferred technique. supported hose tube is placed on the trough

between the two bottom rolls.

This method is used for any rubber hose

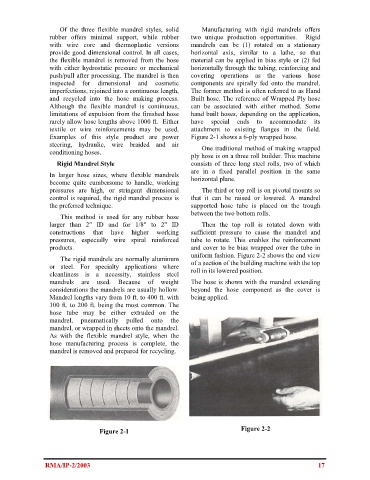

larger than 2" ID and for 1/8" to 2" ID Then the top roll is rotated down with

constructions that have higher working sufficient pressure to cause the mandrel and

pressures, especially wire spiral reinforced tube to rotate. This enables the reinforcement

products. and cover to be bias wrapped over the tube in

uniform fashion. Figure 2-2 shows the end view

The rigid mandrels are normally aluminum

or steel. For specialty applications where of a section of the building machine with the top

cleanliness is a necessity, stainless steel roll in its lowered position.

mandrels are used. Because of weight The hose is shown with the mandrel extending

considerations the mandrels are usually hollow. beyond the hose component as the cover is

Mandrel lengths vary from 10 ft. to 400 ft. with being applied.

100 ft. to 200 ft. being the most common. The

hose tube may be either extruded on the

mandrel, pneumatically pulled onto the

mandrel, or wrapped in sheets onto the mandrel.

As with the flexible mandrel style, when the

hose manufacturing process is complete, the

mandrel is removed and prepared for recycling.

Figure 2-1 Figure 2-2

RMA/IP-2/2003 17