Page 161 - Fluid Fitting 2018_extended

P. 161

®

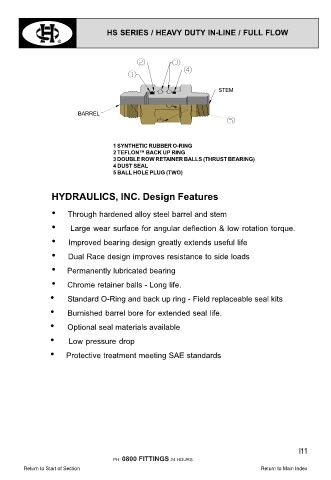

HS SERIES / HEAVY DUTY IN-LINE / FULL FLOW

STEM

®

BARREL HS SERIES / HEAVY DUTY IN-LINE / FULL FLOW

HS SERIES / HEAVY DUTY IN-LINE / FULL FLOW

®

STEM

1 SYNTHETIC RUBBER O-RING

STEM

2 TEFLON™ BACK UP RING

3 DOUBLE ROW RETAINER BALLS (THRUST BEARING)

BARREL BARREL

4 DUST SEAL

5 BALL HOLE PLUG (TWO)

1 SYNTHETIC RUBBER O-RING

2 TEFLON™ BACK UP RING

3 DOUBLE ROW RETAINER BALLS (THRUST BEARING)

1 SYNTHETIC RUBBER O-RING 4 DUST SEAL

5 BALL HOLE PLUG (TWO)

2 TEFLON™ BACK UP RING

3 DOUBLE ROW RETAINER BALLS (THRUST BEARING)

HYDRAULICS, INC. Design Features

4 DUST SEAL HYDRAULICS, INC. Design Features •

• Through hardened alloy steel barrel and stem

5 BALL HOLE PLUG (TWO) • Standard O-Ring and back up ring - Field replaceable seal kits Standard O-Ring and back up ring - Field replaceable seal kits

• Through hardened alloy steel barrel and stem

• Large wear surface for angular deflection & low rotation torque.

• Large wear surface for angular deflection & low rotation torque. • Burnished barrel bore for extended seal life. • Burnished barrel bore for extended seal life.

• Improved bearing design greatly extends useful life • Optional seal materials available

• Improved bearing design greatly extends useful life

• Dual Race design improves resistance to side loads • Low pressure drop • Optional seal materials available

• Permanently lubricated bearing • Protective treatment meeting SAE standards • Low pressure drop

• Dual Race design improves resistance to side loads

• Chrome retainer balls - Long life.

• Permanently lubricated bearing • Protective treatment meeting SAE standards

HYDRAULICS, INC. Design Features • Chrome retainer balls - Long life.

• Through hardened alloy steel barrel and stem • Standard O-Ring and back up ring - Field replaceable seal kits

CAUTION:

Do not attempt to disconnect and disassemble swivels under pressure. Do not remove the swivel barrel from stem while under

• Burnished barrel bore for extended seal life.

• Large wear surface for angular deflection & low rotation torque. pressure. Do not attempt to operate damaged swivels and do not operate swivels displaying fluid leak and/or obvious bearing

wear. Consider that a selected swivels rated pressure cannot exceed the lowest rating of the swivel and of it’s selected ports.

• Optional seal materials available

• Improved bearing design greatly extends useful life Refer to page 3, Safety Information, Selecting and Using Hydraulics, Inc. Swivel Joints.

Pressure Limitations:

• Low pressure drop

• Dual Race design improves resistance to side loads Maximum working pressure for “HS” Series swivels is dependant on port options chosen; however, connecting plumbing may be

rated higher or lower than that of the swivel. The rated working pressure of a fluid power system should not exceed the lowest

• Protective treatment meeting SAE standards

• Permanently lubricated bearing rated component therein.

Installation Information:

CAUTION:

Hydraulics, Inc. swivel joints are generally considered for low speed rotation as encountered in fluid power systems. Maximum

• Chrome retainer balls - Long life. speed of rotation depends upon system environment, with fluid types and extreme conditions related to temperature and pressure

Do not attempt to disconnect and disassemble swivels under pressure. Do not remove the swivel barrel from stem while under

being of prime consideration. Questionable applications should be proven by laboratory or prototype testing. Contamination at

pressure. Do not attempt to operate damaged swivels and do not operate swivels displaying fluid leak and/or obvious bearing

installation should be avoided and connecting plumbing should not cause undue loading. The swivel should not be used as a load

bearing or structural member. Refer to Safety Information - Selecting and Using Hydraulics, Inc. Swivel Joints (page 3) for

additional information.wear. Consider that a selected swivels rated pressure cannot exceed the lowest rating of the swivel and of it’s selected ports.

Refer to page 3, Safety Information, Selecting and Using Hydraulics, Inc. Swivel Joints.

Options:

Swivels shown in this catalog are considered standard to Hydraulics, Inc. For other requirements relative to pressure ratings, port

options, or sizes not shown in this catalog, please contact us. Optional seal materials are available.

Pressure Limitations:

Maximum working pressure for “HS” Series swivels is dependant on port options chosen; however, connecting plumbing may be

rated higher or lower than that of the swivel. The rated working pressure of a fluid power system should not exceed the lowest

CAUTION: rated component therein. I11

Do not attempt to disconnect and disassemble swivels under pressure. Do not remove the swivel barrel from stem while under

PH: 0800 FITTINGS 24 HOURS.

Installation Information:

pressure. Do not attempt to operate damaged swivels and do not operate swivels displaying fluid leak and/or obvious bearing Return to Main Index

Return to Start of Section

Hydraulics, Inc. swivel joints are generally considered for low speed rotation as encountered in fluid power systems. Maximum

wear. Consider that a selected swivels rated pressure cannot exceed the lowest rating of the swivel and of it’s selected ports.

speed of rotation depends upon system environment, with fluid types and extreme conditions related to temperature and pressure

Refer to page 3, Safety Information, Selecting and Using Hydraulics, Inc. Swivel Joints.

being of prime consideration. Questionable applications should be proven by laboratory or prototype testing. Contamination at

installation should be avoided and connecting plumbing should not cause undue loading. The swivel should not be used as a load

Pressure Limitations: bearing or structural member. Refer to Safety Information - Selecting and Using Hydraulics, Inc. Swivel Joints (page 3) for

Maximum working pressure for “HS” Series swivels is dependant on port options chosen; however, connecting plumbing may be

additional information.

rated higher or lower than that of the swivel. The rated working pressure of a fluid power system should not exceed the lowest

rated component therein.

Options:

Installation Information: Swivels shown in this catalog are considered standard to Hydraulics, Inc. For other requirements relative to pressure ratings, port

options, or sizes not shown in this catalog, please contact us. Optional seal materials are available.

Hydraulics, Inc. swivel joints are generally considered for low speed rotation as encountered in fluid power systems. Maximum

speed of rotation depends upon system environment, with fluid types and extreme conditions related to temperature and pressure

being of prime consideration. Questionable applications should be proven by laboratory or prototype testing. Contamination at

installation should be avoided and connecting plumbing should not cause undue loading. The swivel should not be used as a load

bearing or structural member. Refer to Safety Information - Selecting and Using Hydraulics, Inc. Swivel Joints (page 3) for

additional information.

Options:

Swivels shown in this catalog are considered standard to Hydraulics, Inc. For other requirements relative to pressure ratings, port

options, or sizes not shown in this catalog, please contact us. Optional seal materials are available.