Page 401 - Basic Principles of Textile Coloration

P. 401

390 CATIONIC DYES

H3C CH3 OCH3

CH CI Basic Yellow 11

N CH NH charge delocalised

CH3

OCH3

CH3 CH3

N N

CH3

CH3

C

CI Basic Violet 3

charge delocalised

N

CH3 CH3

O NHCH3

CI Basic Blue 22

charge localised

O NH CH2 CH2 CH2 CH3

N

CH3CH3

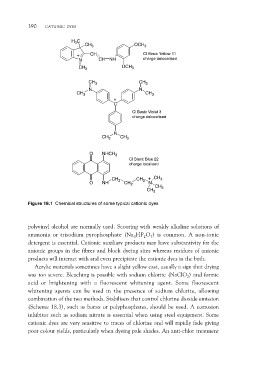

Figure 18.1 Chemical structures of some typical cationic dyes

polyvinyl alcohol are normally used. Scouring with weakly alkaline solutions of

ammonia or trisodium pyrophosphate (Na3HP2O7) is common. A non-ionic

detergent is essential. Cationic auxiliary products may have substantivity for the

anionic groups in the fibres and block dyeing sites whereas residues of anionic

products will interact with and even precipitate the cationic dyes in the bath.

Acrylic materials sometimes have a slight yellow cast, usually a sign that drying

was too severe. Bleaching is possible with sodium chlorite (NaClO2) and formic

acid or brightening with a fluorescent whitening agent. Some fluorescent

whitening agents can be used in the presence of sodium chlorite, allowing

combination of the two methods. Stabilisers that control chlorine dioxide emission

(Scheme 18.3), such as borax or polyphosphates, should be used. A corrosion

inhibitor such as sodium nitrate is essential when using steel equipment. Some

cationic dyes are very sensitive to traces of chlorine and will rapidly fade giving

poor colour yields, particularly when dyeing pale shades. An anti-chlor treatment