Page 48 - Lecture Notes DCC3113

P. 48

Notes:

For complete testing procedure, please refer to MS 30, BS 812, ASTM and AASHTO

For road construction specification, refer to JKR/SPJ/1988 & 2008 and Arahan Teknik Jalan JKR/REAM

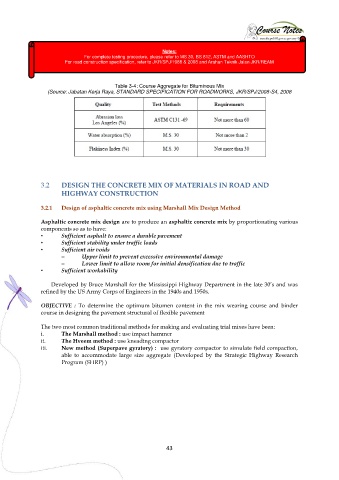

Table 3-4: Course Aggregate for Bituminous Mix

(Source: Jabatan Kerja Raya, STANDARD SPECIFICATION FOR ROADWORKS, JKR/SPJ/2008-S4, 2008

3.2 DESIGN THE CONCRETE MIX OF MATERIALS IN ROAD AND

HIGHWAY CONSTRUCTION

3.2.1 Design of asphaltic concrete mix using Marshall Mix Design Method

Asphaltic concrete mix design are to produce an asphaltic concrete mix by proportionating various

components so as to have:

• Sufficient asphalt to ensure a durable pavement

• Sufficient stability under traffic loads

• Sufficient air voids

– Upper limit to prevent excessive environmental damage

– Lower limit to allow room for initial densification due to traffic

• Sufficient workability

Developed by Bruce Marshall for the Mississippi Highway Department in the late 30’s and was

refined by the US Army Corps of Engineers in the 1940s and 1950s.

OBJECTIVE : To determine the optimum bitumen content in the mix wearing course and binder

course in designing the pavement structural of flexible pavement

The two most common traditional methods for making and evaluating trial mixes have been:

i. The Marshall method : use impact hammer

ii. The Hveem method : use kneading compactor

iii. New method (Superpave gyratory) : use gyratory compactor to simulate field compaction,

able to accommodate large size aggregate (Developed by the Strategic Highway Research

Program (SHRP) )

43