Page 65 - C:\Users\trainee\AppData\Local\Temp\msoEAA3.tmp

P. 65

Document Title

Fundamentals of Stress and Vibration 2. Engineering Mechanics Chapter

[A Practical guide for aspiring Designers / Analysts]

͵ǣ ϐ ǡ ȏ ʹǤͷȐǡ ͳʹ

ǡ ͳͲͲ Ǥ ϐ ͲǤʹǤ

ϐ

ϐ ͲǤ͵Ǥ ǡ

ϐ

Ǥ

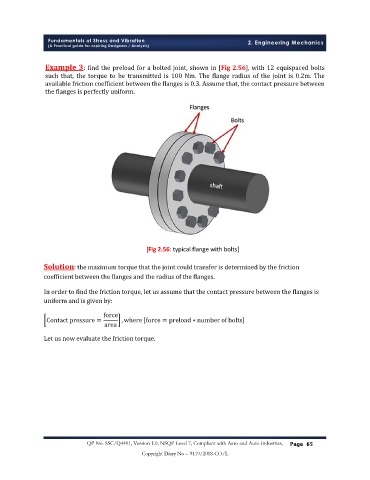

[Fig 2.56: typical flange with bolts]

Solution: the maximum torque that the joint could transfer is determined by the friction

coefficient between the flanges and the radius of the flanges.

In order to find the friction torque, let us assume that the contact pressure between the flanges is

uniform and is given by:

force

Contact pressure = , where force = preload ∗ number of bolts

area

Let us now evaluate the friction torque.

QP No. SSC/Q4401, Version 1.0, NSQF Level 7, Compliant with Aero and Auto Industries, P

Page 65 age 65

Copyright Diary No – 9119/2018-CO/L