Page 68 - E BOOK ENGINE MECHANICAL M2

P. 68

4. SERVICE POINTS OF 4D56 ENGINE COMPONENT

8. Using the special tool Angle gauge (MB991614),

tighten the injector holder bolt in the illustrated se-

quence by a further 120 to 125°.

Fig. 4-19

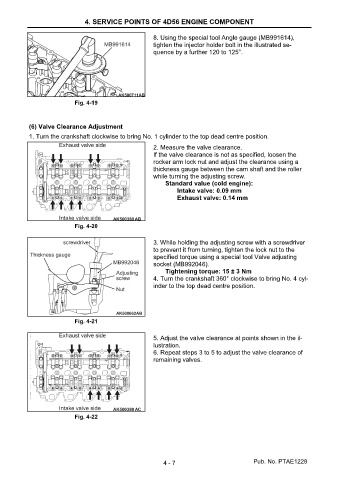

(6) Valve Clearance Adjustment

1. Turn the crankshaft clockwise to bring No. 1 cylinder to the top dead centre position.

2. Measure the valve clearance.

If the valve clearance is not as specified, loosen the

rocker arm lock nut and adjust the clearance using a

thickness gauge between the cam shaft and the roller

while turning the adjusting screw.

Standard value (cold engine):

Intake valve: 0.09 mm

Exhaust valve: 0.14 mm

Fig. 4-20

3. While holding the adjusting screw with a screwdriver

to prevent it from turning, tighten the lock nut to the

specified torque using a special tool Valve adjusting

socket (MB992046).

Tightening torque: 15 ± 3 Nm

4. Turn the crankshaft 360° clockwise to bring No. 4 cyl-

inder to the top dead centre position.

Fig. 4-21

5. Adjust the valve clearance at points shown in the il-

lustration.

6. Repeat steps 3 to 5 to adjust the valve clearance of

remaining valves.

Fig. 4-22

4 - 7 Pub. No. PTAE1228