Page 57 - Arebian

P. 57

57

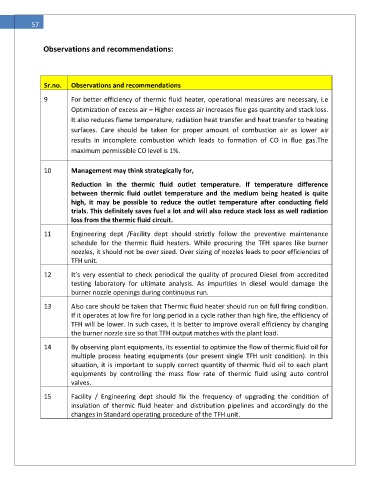

Observations and recommendations:

Sr.no. Observations and recommendations

9 For better efficiency of thermic fluid heater, operational measures are necessary, i.e

Optimization of excess air – Higher excess air increases flue gas quantity and stack loss.

It also reduces flame temperature, radiation heat transfer and heat transfer to heating

surfaces. Care should be taken for proper amount of combustion air as lower air

results in incomplete combustion which leads to formation of CO in flue gas.The

maximum permissible CO level is 1%.

10 Management may think strategically for,

Reduction in the thermic fluid outlet temperature. If temperature difference

between thermic fluid outlet temperature and the medium being heated is quite

high, it may be possible to reduce the outlet temperature after conducting field

trials. This definitely saves fuel a lot and will also reduce stack loss as well radiation

loss from the thermic fluid circuit.

11 Engineering dept /Facility dept should strictly follow the preventive maintenance

schedule for the thermic fluid heaters. While procuring the TFH spares like burner

nozzles, it should not be over sized. Over sizing of nozzles leads to poor efficiencies of

TFH unit.

12 It’s very essential to check periodical the quality of procured Diesel from accredited

testing laboratory for ultimate analysis. As impurities in diesel would damage the

burner nozzle openings during continuous run.

13 Also care should be taken that Thermic fluid heater should run on full firing condition.

If it operates at low fire for long period in a cycle rather than high fire, the efficiency of

TFH will be lower. In such cases, it is better to improve overall efficiency by changing

the burner nozzle size so that TFH output matches with the plant load.

14 By observing plant equipments, its essential to optimize the flow of thermic fluid oil for

multiple process heating equipments (our present single TFH unit condition). In this

situation, it is important to supply correct quantity of thermic fluid oil to each plant

equipments by controlling the mass flow rate of thermic fluid using auto control

valves.

15 Facility / Engineering dept should fix the frequency of upgrading the condition of

insulation of thermic fluid heater and distribution pipelines and accordingly do the

changes in Standard operating procedure of the TFH unit.