Page 14 - MGPI_Case_Study

P. 14

TABLE 2. Mod B fill line chemical incompatibilities; unsafe combinations designated by X (Source: CSB).

44

Sulfuric Sodium Sodium Acetic Propylene

44

Acid Hypochlorite Hydroxide Anhydride Oxide

Sulfuric Acid X X X X

Sodium Hypochlorite 45 X X X

Sodium Hydroxide X X X

Acetic Anhydride 46 X X X X

Propylene Oxide 47 X X X X

must be designed so that it is suitable for the designated task,

avoids unnecessary complexity, and its components must be

recognizable and consistent with user training and experience.

5.1.1 DESIGN OF CHEMICAL TRANSFER EQUIPMENT

5.1.1.1 FILL LINE PROXIMITY

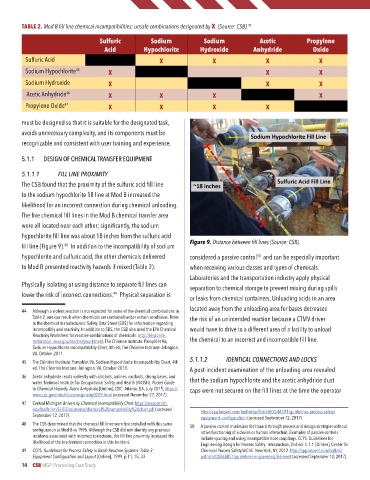

The CSB found that the proximity of the sulfuric acid fill line

to the sodium hypochlorite fill line at Mod B increased the

likelihood for an incorrect connection during chemical unloading.

The five chemical fill lines in the Mod B chemical transfer area

were all located near each other; significantly, the sodium

hypochlorite fill line was about 18 inches from the sulfuric acid

Figure 9. Distance between fill lines (Source: CSB).

fill line (Figure 9). In addition to the incompatibility of sodium

48

hypochlorite and sulfuric acid, the other chemicals delivered considered a passive control and can be especially important

50

to Mod B presented reactivity hazards if mixed (Table 2). when receiving various classes and types of chemicals.

Laboratories and the transportation industry apply physical

Physically isolating or using distance to separate fill lines can

separation to chemical storage to prevent mixing during spills

49

lower the risk of incorrect connections. Physical separation is

or leaks from chemical containers. Unloading acids in an area

located away from the unloading area for bases decreases

44 Although a violent reaction is not expected for some of the chemical combinations in

Table 2, one can result when chemicals are combined under certain conditions. Refer the risk of an unintended reaction because a CTMV driver

to the chemical manufacturers’ Safety Data Sheet (SDS) for information regarding

incompatibly and reactivity. In addition to SDS, the CSB also used the EPA Chemical would have to drive to a different area of a facility to unload

Reactivity Worksheet for reactive combinations of chemicals: http://response.

restoration.noaa.gov/reactivityworksheet. The Chlorine Institute. Pamphlet 96, the chemical to an incorrect and incompatible fill line.

Sodium Hypochlorite Incompatibility Chart, 4th ed; The Chlorine Institute: Arlington,

VA, October 2011.

5.1.1.2 IDENTICAL CONNECTIONS AND LOCKS

45 The Chlorine Institute. Pamphlet 96, Sodium Hypochlorite Incompatibility Chart, 4th

ed; The Chlorine Institute: Arlington, VA, October 2011. A post-incident examination of the unloading area revealed

46 Acetic anhydride reacts violently with alcohols, amines, oxidants, strong bases, and

water. National Institute for Occupational Safety and Health (NIOSH). Pocket Guide that the sodium hypochlorite and the acetic anhydride dust

to Chemical Hazards, Acetic Anhydride [Online], CDC: Atlanta, GA, July 2015, https:// caps were not secured on the fill lines at the time the operator

www.cdc.gov/niosh/ipcsneng/neng0209.html (accessed November 27, 2017).

47 Central Michigan University. Chemical Incompatibility Chart. https://www.cmich.

edu/fas/fsr/rm/EHS/Documents/chemical%20compatibility%20chart.pdf (accessed http://app.knovel.com/hotlink/pdf/id:kt003JMGR1/guidelines-process-safety/

September 12, 2017).

equipment--configuration. (accessed September 12, 2017).

48 The CSB determined that the chemical fill lines were first installed with this same 50 A passive control minimizes the hazard through process and design strategies without

configuration at Mod B in 1996. Although the CSB did not identify any previous active functioning of a device or human interaction. Examples of passive controls

incidents associated with incorrect corrections, the fill line proximity increased the include spacing and using incompatible hose couplings. CCPS. Guidelines for

likelihood of the inadvertent connection in this incident.

Engineering Design for Process Safety--Introduction, 2nd ed. 5.1.1 [Online], Center for

49 CCPS. Guidelines for Process Safety in Batch Reaction Systems--Table 3: Chemical Process Safety/AIChE: New York, NY, 2012. http://app.knovel.com/hotlink/

Equipment Configuration and Layout [Online], 1999, p 11, 15, 33. pdf/id:kt00A68RS1/guidelines-engineering/inherent (accessed September 12, 2017).

14 CSB MGPI Processing Case Study