Page 1259 - YG 2019

P. 1259

COBALT & HSS COBALT & HSS

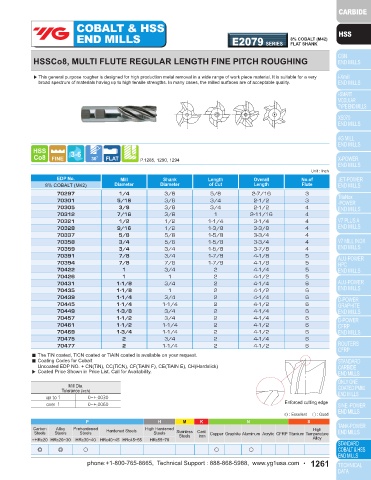

END MILLS E2085 SERIES 8% COBALT (M42) END MILLS E2079 SERIES 8% COBALT (M42)

FLAT SHANK

FLAT SHANK

HSSCo8, MULTI FLUTE REGULAR LENGTH FINE PITCH ROUGHING HSSCo8, MULTI FLUTE REGULAR LENGTH FINE PITCH ROUGHING

CENTER CUTTING

▶This general purpose rougher is designed for high production metal removal in a wide range of work piece material. It is suitable for a very broad ▶ This general purpose rougher is designed for high production metal removal in a wide range of work piece material. It is suitable for a very

spectrum of materials having up to high tensile strengths. In many cases, the milled surfaces are of acceptable quality. broad spectrum of materials having up to high tensile strengths. In many cases, the milled surfaces are of acceptable quality.

P.1285, 1290, 1294 P.1285, 1290, 1294

Unit : Inch Unit : Inch

EDP No. Mill Shank Length Overall No.of EDP No. Mill Shank Length Overall No.of

8% COBALT (M42) Diameter Diameter of Cut Length Flute 8% COBALT (M42) Diameter Diameter of Cut Length Flute

76297 1/4 3/8 5/8 2-7/16 3 70297 1/4 3/8 5/8 2-7/16 3

76301 5/16 3/8 3/4 2-1/2 3 70301 5/16 3/8 3/4 2-1/2 3

76305 3/8 3/8 3/4 2-1/2 4 70305 3/8 3/8 3/4 2-1/2 4

76312 7/16 3/8 1 2-11/16 4 70312 7/16 3/8 1 2-11/16 4

76321 1/2 1/2 1-1/4 3-1/4 4 70321 1/2 1/2 1-1/4 3-1/4 4

76328 9/16 1/2 1-3/8 3-3/8 4 70328 9/16 1/2 1-3/8 3-3/8 4

76337 5/8 5/8 1-5/8 3-3/4 4 70337 5/8 5/8 1-5/8 3-3/4 4

76359 3/4 3/4 1-5/8 3-7/8 4 70358 3/4 5/8 1-5/8 3-3/4 4

76391 7/8 3/4 1-7/8 4-1/8 5 70359 3/4 3/4 1-5/8 3-7/8 4

76394 7/8 7/8 1-7/8 4-1/8 5 70391 7/8 3/4 1-7/8 4-1/8 5

76422 1 3/4 2 4-1/4 5 70394 7/8 7/8 1-7/8 4-1/8 5

76426 1 1 2 4-1/2 5 70422 1 3/4 2 4-1/4 5

■ The TiN coated, TiCN coated or TiAIN coated is available on your request. 70426 1 1 2 4-1/2 5

■ Coating Codes for Cobalt 70431 1-1/8 3/4 2 4-1/4 6

Uncoated EDP NO. + CN(TiN), CC(TiCN), CF(TiAIN F), CE(TiAIN E), CH(Hardslick) 70435 1-1/8 1 2 4-1/2 6

▶ Coated Price Shown in Price List. Call for Availability. 70439 1-1/4 3/4 2 4-1/4 6

70445 1-1/4 1-1/4 2 4-1/2 6

Mill Dia. 70449 1-3/8 3/4 2 4-1/4 6

Tolerance (inch) 70457 1-1/2 3/4 2 4-1/4 6

up to 1 0~+.0030

70461 1-1/2 1-1/4 2 4-1/2 6

over 1 0~+.0060 Enforced cutting edge 70469 1-3/4 1-1/4 2 4-1/2 6

70475 2 3/4 2 4-1/4 6

70477 2 1-1/4 2 4-1/2 6

■ The TiN coated, TiCN coated or TiAIN coated is available on your request.

■ Coating Codes for Cobalt

Uncoated EDP NO. + CN(TiN), CC(TiCN), CF(TiAIN F), CE(TiAIN E), CH(Hardslick)

▶ Coated Price Shown in Price List. Call for Availability.

Mill Dia.

Tolerance (inch)

up to 1 0~+.0030

over 1 0~+.0060 Enforced cutting edge

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened Hardened Steels High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Iron

Steels

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Steels Iron Alloy

◎ ◎ ○ ○ ○ ◎ ◎ ○ ○ ○

1260 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1261