Page 941 - YG 2019

P. 941

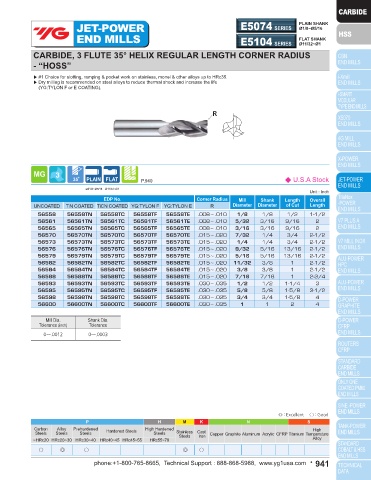

JET-POWER E5075 SERIES PLAIN SHANK JET-POWER E5074 SERIES PLAIN SHANK

Ø1/8~Ø5/16

Ø1/8~Ø5/16

END MILLS E5105 SERIES FLAT SHANK END MILLS E5104 SERIES FLAT SHANK

Ø11/32~Ø1

Ø11/32~Ø1

CARBIDE, 3 FLUTE 35° HELIX STUB LENGTH CORNER RADIUS CARBIDE, 3 FLUTE 35° HELIX REGULAR LENGTH CORNER RADIUS

- “HOSS” - “HOSS”

▶ #1 Choice for slotting, ramping & pocket work on stainless, monel & other alloys up to HRc35. ▶ #1 Choice for slotting, ramping & pocket work on stainless, monel & other alloys up to HRc35.

▶ Dry milling is recommended on steel alloys to reduce thermal shock and increase the life ▶ Dry milling is recommended on steel alloys to reduce thermal shock and increase the life

(YG:TYLON F or E COATING). (YG:TYLON F or E COATING).

R R

↙ ↙

◆ U.S.A Stock P.940 ◆ U.S.A Stock

Ø1/8~Ø5/16 Ø11/32~Ø1 aØ1/8~Ø5/16 Ø11/32~Ø1

Unit : Inch Unit : Inch

EDP No. Corner Radius Mill Shank Length Overall EDP No. Corner Radius Mill Shank Length Overall

UNCOATED TiN COATED TiCN COATED YG:TYLON F YG:TYLON E R Diameter Diameter of Cut Length UNCOATED TiN COATED TiCN COATED YG:TYLON F YG:TYLON E R Diameter Diameter of Cut Length

57558 57558TN 57558TC 57558TF 57558TE .008〜.010 1/8 1/8 1/4 1-1/2 56558 56558TN 56558TC 56558TF 56558TE .008〜.010 1/8 1/8 1/2 1-1/2

57561 57561TN 57561TC 57561TF 57561TE .008〜.010 5/32 3/16 5/16 2 56561 56561TN 56561TC 56561TF 56561TE .008〜.010 5/32 3/16 9/16 2

57565 57565TN 57565TC 57565TF 57565TE .008〜.010 3/16 3/16 5/16 2 56565 56565TN 56565TC 56565TF 56565TE .008〜.010 3/16 3/16 9/16 2

57570 57570TN 57570TC 57570TF 57570TE .015〜.020 7/32 1/4 3/8 2 56570 56570TN 56570TC 56570TF 56570TE .015〜.020 7/32 1/4 3/4 2-1/2

57573 57573TN 57573TC 57573TF 57573TE .015〜.020 1/4 1/4 3/8 2 56573 56573TN 56573TC 56573TF 56573TE .015〜.020 1/4 1/4 3/4 2-1/2

57576 57576TN 57576TC 57576TF 57576TE .015〜.020 9/32 5/16 7/16 2 56576 56576TN 56576TC 56576TF 56576TE .015〜.020 9/32 5/16 13/16 2-1/2

57579 57579TN 57579TC 57579TF 57579TE .015〜.020 5/16 5/16 7/16 2 56579 56579TN 56579TC 56579TF 56579TE .015〜.020 5/16 5/16 13/16 2-1/2

57582 57582TN 57582TC 57582TF 57582TE .015〜.020 11/32 3/8 1/2 2 56582 56582TN 56582TC 56582TF 56582TE .015〜.020 11/32 3/8 1 2-1/2

57584 57584TN 57584TC 57584TF 57584TE .015〜.020 3/8 3/8 1/2 2 56584 56584TN 56584TC 56584TF 56584TE .015〜.020 3/8 3/8 1 2-1/2

57588 57588TN 57588TC 57588TF 57588TE .015〜.020 7/16 7/16 9/16 2-1/2 56588 56588TN 56588TC 56588TF 56588TE .015〜.020 7/16 7/16 1 2-3/4

57593 57593TN 57593TC 57593TF 57593TE .030〜.035 1/2 1/2 5/8 2-1/2 56593 56593TN 56593TC 56593TF 56593TE .030〜.035 1/2 1/2 1-1/4 3

57595 57595TN 57595TC 57595TF 57595TE .030〜.035 5/8 5/8 3/4 3 56595 56595TN 56595TC 56595TF 56595TE .030〜.035 5/8 5/8 1-5/8 3-1/2

57598 57598TN 57598TC 57598TF 57598TE .030〜.035 3/4 3/4 1 3 56598 56598TN 56598TC 56598TF 56598TE .030〜.035 3/4 3/4 1-5/8 4

57600 57600TN 57600TC 57600TF 57600TE .030〜.035 1 1 1-1/4 3 56600 56600TN 56600TC 56600TF 56600TE .030〜.035 1 1 2 4

Mill Dia. Shank Dia.

Tolerance (inch) Tolerance Mill Dia. Shank Dia.

Tolerance (inch) Tolerance

0~-.0012 0~-.0003

0~-.0012 0~-.0003

RECOMMENDED CUTTING CONDITIONS

▶ Use stub length whenever possible

▶ Hardslick coating is recommended on soft gummy material

Especially on tools 3/16 and under SFM

CUTTING TOOL DIAMETER

1/8 .0003~.0015 3/8 .0015~.0035 3/4 .003~.006

3/16 .0004~.002 7/16 .002~.004 1 .003~.007

1/4 .001~.0025 1/2 .0025~.0045

5/16 .0015~.003 5/8 .0025~.005

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ◎ ○ ◎ ○ ○ ◎ ○ ◎ ○

940 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 941