Page 412 - CarrLaneCatalog_2019ed-c.pdf

P. 412

INTRODUCTION

What exactly is modular fixturing? In many ways modular fixturing GRID HOLES VS. EARLIER T-SLOT SYSTEMS:

is just like permanent fixturing, except for a few key differences. The two primary forms of modular systems available today are

First, modular fixtures can be assembled entirely from reusable those with grid-pattern holes and earlier types with T slots to

off-the-shelf components, without machining. Next, many modular mount components. Grid holes offer many advantages over T

components are adjustable and universal. Finally, specially slots. Modular systems with grid holes have greater positional

designed tooling plates and blocks, with a standard grid pattern, accuracy and strength than those with T slots. T-slot systems

are the foundation of a good modular system. permit movement along the slot, so nothing but friction holds

components in place. Wherever T slots cross each other, a weak

point exists.

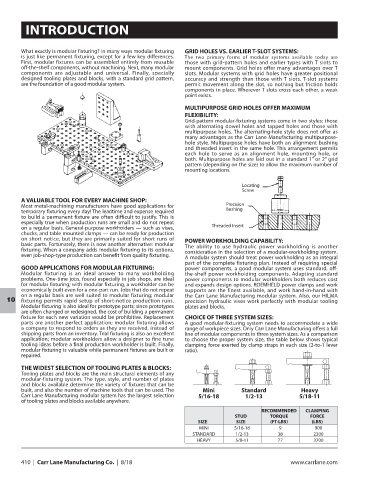

MULTIPURPOSE GRID HOLES OFFER MAXIMUM

FLEXIBILITY:

Grid-pattern modular-fixturing systems come in two styles: those

with alternating dowel holes and tapped holes and those with

multipurpose holes. The alternating-hole style does not offer as

many advantages as the Carr Lane Manufacturing multipurpose-

hole style. Multipurpose holes have both an alignment bushing

and threaded insert in the same hole. This arrangement permits

each hole to serve as an alignment hole, mounting hole, or

both. Multipurpose holes are laid out in a standard 1” or 2” grid

pattern (depending on the size) to allow the maximum number of

mounting locations.

Locating

Screw

A VALUABLE TOOL FOR EVERY MACHINE SHOP:

Most metal-machining manufacturers have good applications for Precision

temporary fixturing every day! The leadtime and expense required Bushing

to build a permanent fixture are often difficult to justify. This is

especially true when production runs are small and do not repeat

on a regular basis. General-purpose workholders — such as vises, Threaded Insert

chucks, and table mounted clamps — can be ready for production

on short notice, but they are primarily suited for short runs of POWER WORKHOLDING CAPABILITY:

basic parts. Fortunately, there is now another alternative: modular The ability to use hydraulic power workholding is another

fixturing. When a company adds modular fixturing to its options, consideration in the selection of a modular-workholding system.

even job-shop-type production can benefit from quality fixturing.

A modular system should treat power workholding as an integral

part of the complete fixturing plan. Instead of requiring special

GOOD APPLICATIONS FOR MODULAR FIXTURING: power components, a good modular system uses standard, off-

Modular fixturing is an ideal answer to many workholding the-shelf power workholding components. Adapting standard

problems. One-time jobs, found especially in job shops, are ideal power components to modular workholders both reduces cost

for modular fixturing; with modular fixturing, a workholder can be and expands design options. ROEMHELD power clamps and work

economically built even for a one-part run. Jobs that do not repeat supports are the finest available, and work hand-in-hand with

on a regular basis are well suited to modular fixturing; modular the Carr Lane Manufacturing modular system. Also, our HILMA

fixturing permits rapid setup of short-notice production runs.

10 precision hydraulic vises work perfectly with modular tooling

Modular fixturing is also ideal for prototype parts; since prototypes plates and blocks.

are often changed or redesigned, the cost of building a permanent

fixture for each new variation would be prohibitive. Replacement CHOICE OF THREE SYSTEM SIZES:

parts are another perfect application; modular fixturing allows A good modular-fixturing system needs to accommodate a wide

a company to respond to orders as they are received, instead of range of workpiece sizes. Only Carr Lane Manufacturing offers a full

shipping parts from an inventory. Trial fixturing is also an excellent line of modular components in three system sizes. As a comparison

application; modular workholders allow a designer to fine tune to choose the proper system size, the table below shows typical

tooling ideas before a final production workholder is built. Finally, clamping force exerted by clamp straps in each size (2-to-1 lever

modular fixturing is valuable while permanent fixtures are built or ratio).

repaired.

THE WIDEST SELECTION OF TOOLING PLATES & BLOCKS:

Tooling plates and blocks are the main structural elements of any

modular-fixturing system. The type, style, and number of plates

and blocks available determine the variety of fixtures that can be

built, and also the number of machine tools that can be used. The Mini Standard Heavy

Carr Lane Manufacturing modular system has the largest selection 5/16-18 1/2-13 5/18-11

of tooling plates and blocks available anywhere.

RECOMMENDED CLAMPING

STUD TORQUE FORCE

SIZE SIZE (FT-LBS) (LBS)

MINI 5/16-18 9 900

STANDARD 1/2-13 38 2300

HEAVY 5/8-11 77 3700

410 | Carr Lane Manufacturing Co. | 8/18 www.carrlane.com