Page 416 - CarrLaneCatalog_2019ed-c.pdf

P. 416

TECHNICAL INFORMATION

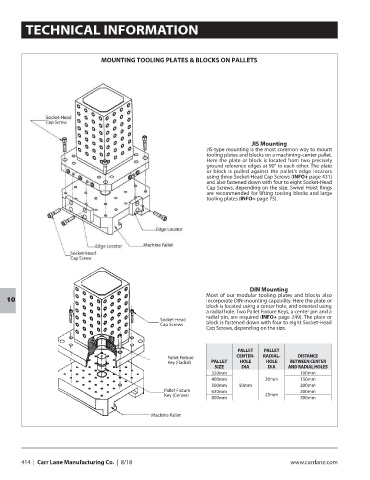

MOUNTING TOOLING PLATES & BLOCKS ON PALLETS

JIS Mounting

JIS-type mounting is the most common way to mount

tooling plates and blocks on a machining-center pallet.

Here the plate or block is located from two precisely

ground reference edges at 90° to each other. The plate

or block is pulled against the pallet’s edge locators

using three Socket-Head Cap Screws (INFO+ page 431)

and also fastened down with four to eight Socket-Head

Cap Screws, depending on the size. Swivel Hoist Rings

are recommended for lifting tooling blocks and large

tooling plates (INFO+ page 75).

DIN Mounting

Most of our modular tooling plates and blocks also

incorporate DIN-mounting capability. Here the plate or

10

block is located using a center hole, and oriented using

a radial hole. Two Pallet Fixture Keys, a center pin and a

radial pin, are required (INFO+ page 249). The plate or

Socket-Head

Cap Screws block is fastened down with four to eight Socket-Head

Cap Screws, depending on the size.

PALLET PALLET

Pallet Fixture CENTER- RADIAL- DISTANCE

Key (Radial) PALLET HOLE HOLE BETWEEN CENTER

SIZE DIA DIA AND RADIAL HOLES

320mm 100mm

400mm 20mm 150mm

500mm 50mm 200mm

Pallet Fixture 630mm 200mm

Key (Center) 25mm

800mm 300mm

Machine Pallet

414 | Carr Lane Manufacturing Co. | 8/18 www.carrlane.com