Page 626 - CarrLaneCatalog_2019ed-c.pdf

P. 626

Design Information

Choose enough load capacity to resist:

(1) ma chining forces; (2) workpiece weight; (3)

clamping forces not resisted by fixed stops.

3. Machine-tool interlock. In automated

systems where timing and synchronization are via hose, tubing, or drilled passages. When

important, double-acting clamps are the best hydraulic pressure acts on a clamp’s piston

When supporting underneath a clamp, as choice. By installing pressure switches in both area, it generates external force according

in the example above, load capacity should clamping and return lines, a machine controller to the physical relationship F=P x A:

be substantially greater than clamping knows exact clamp status at all times.

force. Not only must the support resist static

clamping force, it must resist dynamic load 8. Clamping Time

too (the “hammering” due to clamping-arm Hydraulic clamping is usually fast, but not

mo men tum). We recommend a load capacity instantaneous. To estimate clamping time,

of at least 2 times the clamping force. Another consider the two phases of clamping:

factor when clamping over a work support is 1. Extending time, under low-pressure

that the clamp may build up force faster than free flow

the support builds up load capacity. To avoid 2. Pressure-building time

this, use a sequence valve to delay clamping

until load capacity builds up.

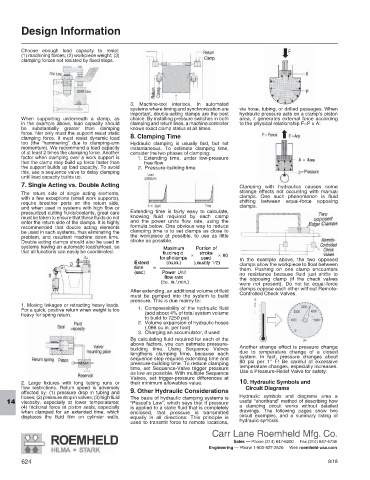

7. Single Acting vs. Double Acting Clamping with hydraulics causes some

The return side of single acting elements, strange effects not occurring with manual

with a few exceptions (small work supports), clamps. One such phenomenon is fluid

require breather ports on the return side, shifting between equal-force opposing

and when used in systems with high flow or clamps.

pressurized cutting fluids/coolants, great care Extending time is fairly easy to calculate,

must be taken to ensure that these fluids do not knowing fluid required by each clamp

enter the return side of the clamps. It is highly and the power units flow rate, using the

recommended that double acting elements formula below. One obvious way to reduce

be used in such systems, thus eliminating the clamping time is to set clamps as close to

problem, and resultant machine down time. the workpiece at possible, to use as little

Double acting clamps should also be used in stroke as possible.

systems having an automatic load/unload, so

that all functions can easily be coordinated.

In the example above, the two opposed

clamps allow the workpiece to float between

them. Pushing on one clamp encounters

no resistance because fluid just shifts to

the opposing clamp (if the check valves

were not present). Do not let equal-force

clamps oppose each other without Remote-

After extending, an additional volume of fluid Controlled Check Valves.

must be pumped into the system to build

pressure. This is due mainly to:

1. Moving linkages or retracting heavy loads.

For a quick, positive return when weight is too 1. Compressibility of the hydraulic fluid

heavy for spring return. (add about 4% of total system volume

to build to 7250 psi)

2. Volume expansion of hydraulic hoses

(.066 cu.in. per foot)

3. Charging an accumulator, if used

By calculating fluid required for each of the

above factors, you can estimate pressure-

building time. Using Sequence Valves Another strange effect is pressure change

lengthens clamping time, because each due to temperature change of a closed

sequence step requires extending time and system. In fact, pressure changes about

pressure-building time. To reduce clamping 80 psi per 1° F! Be careful of excessive

time, set Sequence-Valve trigger pressure temperature changes, especially increases.

as low as possible. With multiple Sequence Use a Pressure-Relief Valve for safety.

Valves, set trigger-pressure differences at

2. Large fixtures with long tubing runs or their minimum allowables value. 10. Hydraulic Symbols and

flow restrictions. Return speed is adversely Circuit Diagrams

affected by: (1) pressure drop in tubing and 9. Other Hydraulic Considerations

hoses; (2) pressure drop in valves; (3) high fluid The basis of hydraulic clamping systems is Hydraulic symbols and diagrams area a

viscosity, especially at lower temperatures; “Pascal’s Law”, which says that if pressure useful “shorthand” method of describing how

14

(4) frictional force at piston seals, especially is applied to a static fluid that is completely a clamping circuit works without detailed

when clamped for an extended time, which enclosed, that pressure is transmitted drawings. The following pages show two

displaces the fluid film on cylinder walls. equally in all directions: This principle is circuit examples, and a summary listing of

used to transmit force to remote locations, hydraulic symbols.

Carr Lane Roemheld Mfg. Co.

Sales — Phone (314) 647-6200 Fax (314) 647-5736

Engineering — Phone 1-800-827-2526 Web roemheld-usa.com

624 8/18