Page 630 - CarrLaneCatalog_2019ed-c.pdf

P. 630

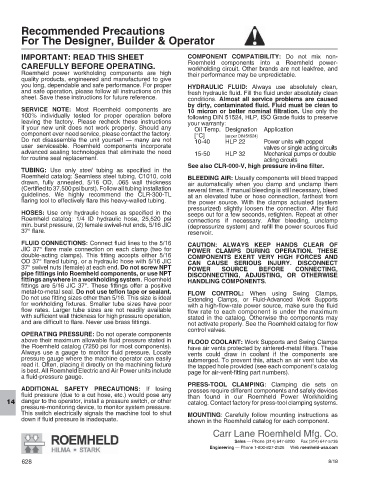

Recommended Precautions

For The Designer, Builder & Operator

IMPORTANT: READ THIS SHEET COMPONENT COMPATIBILITY: Do not mix non-

Roemheld components into a Roemheld power-

CAREFULLY BEFORE OPERATING. workholding circuit. Other brands are not leakfree, and

Roemheld power workholding components are high their performance may be unpredictable.

quality products, engineered and manufactured to give

you long, dependable and safe performance. For proper HYDRAULIC FLUID: Always use absolutely clean,

and safe operation, please follow all instructions on this fresh hydraulic fluid. Fill the fluid under absolutely clean

sheet. Save these instructions for future reference. conditions. Almost all service problems are caused

by dirty, contaminated fluid. Fluid must be clean to

SERVICE NOTE: Most Roemheld components are 10 micron or better nominal filtration. Use only the

100% individually tested for proper operation before following DIN 51524, HLP, ISO Grade fluids to preserve

leaving the factory. Please recheck these instructions your warranty:

if your new unit does not work properly. Should any Oil Temp. Designation Application

component ever need service, please contact the factory. [°C] [as per DIN 51524]

Do not disassemble the unit yourself — many are not 10-40 HLP 22 Power units with poppet

user serviceable. Roemheld components incorporate valves or single acting circuits

advanced sealing technologies that eliminate the need 15-50 HLP 32 Mechanical pumps or double

for routine seal replacement. acting circuits

See also CLR-000-V, high pressure in-line filter.

TUBING: Use only steel tubing as specified in the

Roemheld catalog: Seamless steel tubing, C1010, cold BLEEDING AIR: Usually components will bleed trapped

drawn, fully annealed, 5/16 OD, .065 wall thickness air automatically when you clamp and unclamp them

(Certified to 37,500 psi burst). Follow all tubing installation several times. If manual bleeding is still necessary, bleed

guidelines. We highly recommend the CLR-300-TL at an elevated tube or hose connection, farthest from

flaring tool to effectively flare this heavy-walled tubing. the power source. With the clamps actuated (system

pressurized) slightly loosen the connection. After fluid

HOSES: Use only hydraulic hoses as specified in the seeps out for a few seconds, retighten. Repeat at other

Roemheld catalog: 1/4 ID hydraulic hose, 25,520 psi connections if necessary. After bleeding, unclamp

min. burst pressure, (2) female swivel-nut ends, 5/16 JIC (depressurize system) and refill the power sources fluid

37° flare. reservoir.

FLUID CONNECTIONS: Connect fluid lines to the 5/16 CAUTION: ALWAYS KEEP HANDS CLEAR OF

JIC 37° flare male connection on each clamp (two for POWER CLAMPS DURING OPERATION. THESE

double-acting clamps). This fitting accepts either 5/16 COMPONENTS EXERT VERY HIGH FORCES AND

OD 37° flared tubing, or a hydraulic hose with 5/16 JIC CAN CAUSE SERIOUS INJURY. DISCONNECT

37° swivel nuts (female) at each end. Do not screw NPT POWER SOURCE BEFORE CONNECTING,

pipe fittings into Roemheld components, or use NPT DISCONNECTING, ADJUSTING, OR OTHERWISE

fittings anywhere in a workholding system. Roemheld HANDLING COMPONENTS.

fittings are 5/16 JIC 37°. These fittings offer a positive

metal-to-metal seal. Do not use teflon tape or sealant. FLOW CONTROL: When using Swing Clamps,

Do not use fitting sizes other than 5/16. This size is ideal Extending Clamps, or Fluid-Advanced Work Supports

for workholding fixtures. Smaller tube sizes have poor with a high-flow-rate power source, make sure the fluid

flow rates. Larger tube sizes are not readily available flow rate to each component is under the maximum

with sufficient wall thickness for high pressure operation, stated in the catalog. Otherwise the components may

and are difficult to flare. Never use brass fittings. not activate properly. See the Roemheld catalog for flow

control valves.

OPERATING PRESSURE: Do not operate components

above their maximum allowable fluid pressure stated in FLOOD COOLANT: Work Supports and Swing Clamps

the Roemheld catalog (7250 psi for most components). have air vents protected by sintered-metal filters. These

Always use a gauge to monitor fluid pressure. Locate vents could draw in coolant if the components are

pressure gauge where the machine operator can easily submerged. To prevent this, attach an air vent tube via

read it. Often, placing it directly on the machining fixture the tapped hole provided (see each component’s catalog

is best. All Roemheld Electric and Air Power units include page for air-vent-fitting part numbers).

a fluid-pressure gauge.

PRESS-TOOL CLAMPING: Clamping die sets on

ADDITIONAL SAFETY PRECAUTIONS: If losing presses require different components and safety devices

fluid pressure (due to a cut hose, etc.) would pose any than found in our Roemheld Power Workholding

danger to the operator, install a pressure switch, or other

14 catalog. Contact factory for press-tool clamping systems.

pressure-monitoring device, to monitor system pressure.

This switch electrically signals the machine tool to shut MOUNTING: Carefully follow mounting instructions as

down if fluid pressure is inadequate. shown in the Roemheld catalog for each component.

Carr Lane Roemheld Mfg. Co.

Sales — Phone (314) 647-6200 Fax (314) 647-5736

Engineering — Phone 1-800-827-2526 Web roemheld-usa.com

628 8/18