Page 631 - CarrLaneCatalog_2019ed-c.pdf

P. 631

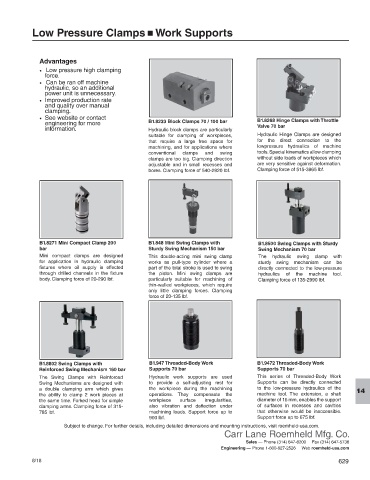

Low Pressure Clamps Work Supports

J

Advantages

• Low pressure high clamping

force.

• Can be ran off machine

hydraulic, so an additional

power unit is unnecessary.

• Improved production rate

and quality over manual

clamping.

• See website or contact B1.8268 Hinge Clamps with Throttle

engineering for more B1.8233 Block Clamps 70 / 100 bar

information. Hydraulic block clamps are particularly Valve 70 bar

suitable for clamping of workpieces, Hydraulic Hinge Clamps are designed

that require a large free space for for the direct connection to the

machining, and for applications where lowpressure hydraulics of machine

conventional clamps and swing tools. Special kinematics allow clamping

clamps are too big. Clamping direction without side loads of workpieces which

adjustable and in small recesses and are very sensitive against deformation.

bores. Clamping force of 540-2920 lbf. Clamping force of 515-3865 lbf.

B1.8271 Mini Compact Clamp 200 B1.848 Mini Swing Clamps with B1.8500 Swing Clamps with Sturdy

bar Sturdy Swing Mechanism 150 bar Swing Mechanism 70 bar

Mini compact clamps are designed This double-acting mini swing clamp The hydraulic swing clamp with

for application in hydraulic clamping works as pull-type cylinder where a sturdy swing mechanism can be

fixtures where oil supply is effected part of the total stroke is used to swing directly connected to the low-pressure

through drilled channels in the fixture the piston. Mini swing clamps are hydraulics of the machine tool.

body. Clamping force of 20-290 lbf. particularly suitable for machining of Clamping force of 135-2990 lbf.

thin-walled workpieces, which require

only little clamping forces. Clamping

force of 20-135 lbf.

B1.8802 Swing Clamps with B1.947 Threaded-Body Work B1.9472 Threaded-Body Work

Reinforced Swing Mechanism 160 bar Supports 70 bar Supports 70 bar

The Swing Clamps with Reinforced Hydraulic work supports are used This series of Threaded-Body Work

Swing Mechanisms are designed with to provide a self-adjusting rest for Supports can be directly connected

a double clamping arm which gives the workpiece during the machining to the low-pressure hydraulics of the

the ability to clamp 2 work pieces at operations. They compensate the machine tool. The extension, a shaft 14

the same time. Forked head for simple workpiece surface irregularities, diameter of 16 mm, enables the support

clamping arms. Clamping force of 315- also vibration and deflection under of surfaces in recesses and cavities

785 lbf. machining loads. Support force up to that otherwise would be inaccessible.

900 lbf. Support force up to 675 lbf.

Subject to change. For further details, including detailed dimensions and mounting instructions, visit roemheld-usa.com.

Carr Lane Roemheld Mfg. Co.

Sales — Phone (314) 647-6200 Fax (314) 647-5736

Engineering — Phone 1-800-827-2526 Web roemheld-usa.com

8/18 629