Page 663 - CarrLaneCatalog_2019ed-c.pdf

P. 663

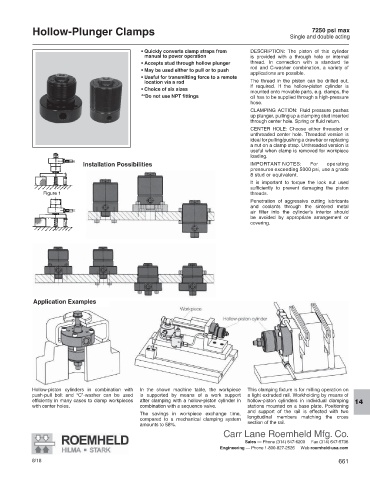

Hollow-Plunger Clamps 7250 psi max

Single and double acting

• Quickly converts clamp straps from DESCRIPTION: The piston of this cylinder

manual to power operation is provided with a through hole or internal

• Accepts stud through hollow plunger thread. In connection with a standard tie

rod and C-washer combination, a variety of

• May be used either to pull or to push

applications are possible.

• Useful for transmitting force to a remote

location via a rod The thread in the piston can be drilled out,

if required. If the hollow-piston cylinder is

• Choice of six sizes

mounted onto movable parts, e.g. clamps, the

**Do not use NPT fittings oil has to be supplied through a high-pressure

hose.

CLAMPING ACTION: Fluid pressure pushes

up plunger, pulling up a clamping stud inserted

through center hole. Spring or fluid return.

CENTER HOLE: Choose either threaded or

unthreaded center hole. Threaded version is

ideal for pulling/pushing a drawbar or replacing

a nut on a clamp strap. Unthreaded version is

useful when clamp is removed for workpiece

loading.

Installation Possibilities IMPORTANT NOTES: For operating

pressures exceeding 5000 psi, use a grade

8 stud or equivalent.

It is important to torque the lock nut used

sufficiently to prevent damaging the piston

Figure 1 threads.

Penetration of aggressive cutting lubricants

and coolants through the sintered metal

air filter into the cylinder’s interior should

be avoided by appropriate arrangement or

covering.

Application Examples

Hollow-piston cylinders in combination with In the shown machine table, the workpiece This clamping fixture is for milling operation on

push-pull bolt and “C”-washer can be used is supported by means of a work support a light extruded rail. Workholding by means of

efficiently in many cases to clamp workpieces after clamping with a hollow-piston cylinder in hollow-piston cylinders in individual clamping

with center holes. combination with a sequence valve. stations mounted on a base plate. Positioning 14

and support of the rail is effected with two

The savings in workpiece exchange time,

compared to a mechanical clamping system longitudinal members matching the cross

amounts to 58%. section of the rail.

Carr Lane Roemheld Mfg. Co.

Sales — Phone (314) 647-6200 Fax (314) 647-5736

Engineering — Phone 1-800-827-2526 Web roemheld-usa.com

8/18 661