Page 667 - CarrLaneCatalog_2019ed-c.pdf

P. 667

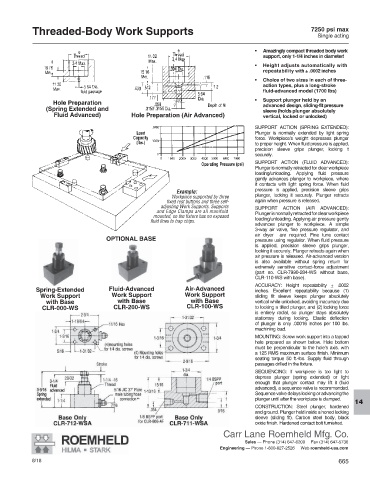

Threaded-Body Work Supports 7250 psi max

Single acting

• Amazingly compact threaded body work

support, only 1-1/4 inches in diameter!

• Height adjusts automatically with

repeatability with + .0002 inches

• Choice of two sizes in each of three-

action types, plus a long-stroke

fluid-advanced model (1700 lbs)

• Support plunger held by an

Hole Preparation advanced design, sliding-fit pressure

(Spring Extended and sleeve (holds plunger absolutely

Fluid Advanced) Hole Preparation (Air Advanced) vertical, locked or unlocked)

SUPPORT ACTION (SPRING EXTENDED):

Plunger is normally extended by light spring

force. Workpiece’s weight depresses plunger

to proper height. When fluid pressure is applied,

precision sleeve grips plunger, locking it

securely.

SUPPORT ACTION (FLUID ADVANCED):

Plunger is normally retracted for clear workpiece

loading/unloading. Applying fluid pressure

gently advances plunger to workpiece, where

it contacts with light spring force. When fluid

Example: pressure is applied, precision sleeve grips

Workpiece supported by three plunger, locking it securely. Plunger retracts

fixed rest buttons and three self- again when pressure is released.

adjusting Work Supports. Supports SUPPORT ACTION (AIR ADVANCED):

and Edge Clamps are all manifold Plunger is normally retracted for clear workpiece

mounted, so the fixture has no exposed

fluid lines to trap chips. load ing/unloading. Applying air pressure gently

ad vances plunger to workpiece. A simple

3-way air valve, fine pressure regulator, and

air dryer are required. Fine tune contact

OPTIONAL BASE pressure using regulator. When fluid pressure

is ap plied, precision sleeve grips plunger,

locking it se curely. Plunger retracts again when

air pressure is released. Air-advanced version

is also available without spring return for

extremely sensitive contact-force adjustment

(part no. CLR-7990-284-WS without base,

CLR-110-WS with base).

ACCURACY: Height repeatability + .0002

Spring-Extended Fluid-Advanced Air-Advanced inches. Excellent repeatability because (1)

Work Support Work Support Work Support slid ing fit sleeve keeps plunger absolutely

with Base with Base with Base vertical while unlocked, avoiding inacurracy due

CLR-000-WS CLR-200-WS CLR-100-WS to lock ing a tilted plunger, and (2) locking force

is en tire ly radial, so plunger stays absolutely

stationary during locking. Elastic deflection

of plunger is only .00016 inches per 100 lbs.

machining load.

MOUNTING: Screw work support into a tapped

hole prepared as shown below. Hole bottom

must be perpendicular to the hole’s axis. with

a 125 RMS maximum surface finish. Minimum

seating torque 50 ft.-lbs. Supply fluid through

passages drilled in the fixture.

SEQUENCING: If workpiece is too light to

depress plunger (spring extended) or light

enough that plunger contact may lift it (fluid

advanced), a sequence valve is recommended.

Sequence valve delays locking or advancing the

plunger until after the workplace is clamped.

14

CONSTRUCTION: Steel plunger, hardened

and ground. Plunger held inside a honed locking

sleeve (sliding fit). Carbon steel body, black

oxide finish. Hardened contact bolt furnished.

Carr Lane Roemheld Mfg. Co.

Sales — Phone (314) 647-6200 Fax (314) 647-5736

Engineering — Phone 1-800-827-2526 Web roemheld-usa.com

8/18 665