Page 701 - CarrLaneCatalog_2019ed-c.pdf

P. 701

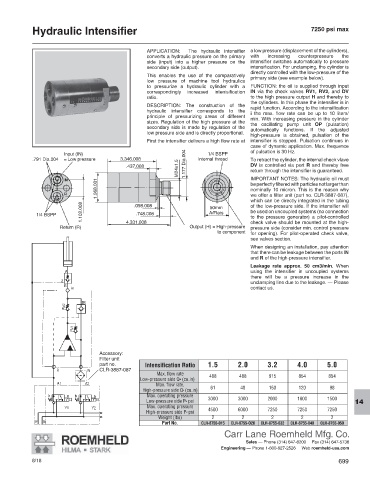

Hydraulic Intensifier 7250 psi max

APPLICATION: The hydraulic intensifier a low pressure (displacement of the cylinders),

converts a hydraulic pressure on the primary with increasing counterpressure the

side (input) into a higher pressure on the intensifier switches automatically to pressure

secondary side (output). intensification. For unclamping, the cylinder is

directly controlled with the low-pressure of the

This enables the use of the comparatively primary side (see example below).

low pressure of machine tool hydraulics

to pressurize a hydraulic cylinder with a FUNCTION: the oil is supplied through input

correspondingly increased intenisification IN via the check valves RV1, RV2, and DV

ratio. to the high pressure output H and thereby to

the cylinders. In this phase the intensifier is in

DESCRIPTION: The construction of the

rapid function. According to the in ten sification

hydraulic intensifier corresponds to the

i the max. flow rate can be up to 10 liters/

principle of pressurizing areas of different

min. With increasing pressure in the cylinder

sizes. Regulation of the high pressure at the

the oscillating pump unit OP (pulsation)

secondary side is made by regulation of the

automatically functions. If the adjusted

low pressure side and is directly proportional.

high-pressure is obtained, pulsation of the

First the intensifier delivers a high flow rate at intensifier is stopped. Pulsation continues in

case of dynamic application. Max. frequence

of pulsation is 30 Hz.

To retract the cylinder, the internal check vlave

DV is controlled via port R and thereby free

return through the intensifier is guaranteed.

IMPORTANT NOTES: The hydraulic oil must

be perfectly filtered with particles not larger than

nominally 10 micron. This is the reason why

we offer a filter unit (part no. CLR-3887-087),

which can be directly integrated in the tubing

of the low-pressure side. If the intensifier will

be used on uncoupled systems (no connection

to the pressure generator) a pilot-controlled

check valve should be mounted at the high-

pressure side (consider min. control pressure

for opening). For pilot-operated check valve,

see valves section.

When designing an installation, pay attention

that there can be leakage between the ports IN

and R of the high-pressure intensifier.

Leakage rate approx. 50 cm3/min. When

using the intensifier in uncoupled systems

there will be a pressure increase in the

unclamping line due to the leakage. — Please

contact us.

Accessory:

Filter unit

part no. Intensification Ratio 1.5 2.0 3.2 4.0 5.0

CLR-3887-087

Max. flow rate 488 488 915 854 854

Low-pressure side Q IN (cu.in)

Max. flow rate,

High-pressure side Q H (cu.in) 61 48 150 120 98

Max. operating pressure

Low-pressure side P IN psi 3000 3000 2000 1800 1500

14

Max. operating pressure

High-pressure side P H psi 4500 6000 7250 7250 7250

Weight (lbs) 2 2 2 2 2

Part No. CLR-8755-015 CLR-8755-O20 CLR-8755-032 CLR-8755-040 CLR-8755-050

Carr Lane Roemheld Mfg. Co.

Sales — Phone (314) 647-6200 Fax (314) 647-5736

Engineering — Phone 1-800-827-2526 Web roemheld-usa.com

8/18 699