Page 153 - Robot Design Handbook ROBOCON Malaysia 2019

P. 153

The mechanical division of the team focuses on the design, prototyping and manufacturing

of the thrower, robotic arm and supporting truss for both robots.

2.1.1 The Robots

Slider

Thrower

Gripper

Sprocket

Chain

(a) (b)

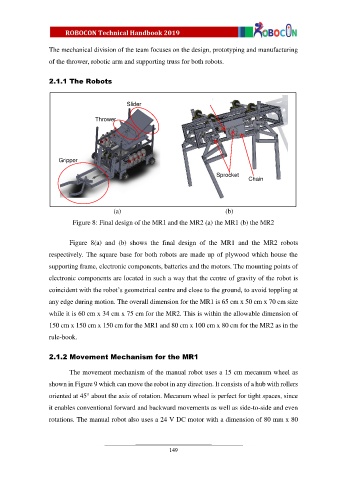

Figure 8: Final design of the MR1 and the MR2 (a) the MR1 (b) the MR2

Figure 8(a) and (b) shows the final design of the MR1 and the MR2 robots

respectively. The square base for both robots are made up of plywood which house the

supporting frame, electronic components, batteries and the motors. The mounting points of

electronic components are located in such a way that the centre of gravity of the robot is

coincident with the robot’s geometrical centre and close to the ground, to avoid toppling at

any edge during motion. The overall dimension for the MR1 is 65 cm x 50 cm x 70 cm size

while it is 60 cm x 34 cm x 75 cm for the MR2. This is within the allowable dimension of

150 cm x 150 cm x 150 cm for the MR1 and 80 cm x 100 cm x 80 cm for the MR2 as in the

rule-book.

2.1.2 Movement Mechanism for the MR1

The movement mechanism of the manual robot uses a 15 cm mecanum wheel as

shown in Figure 9 which can move the robot in any direction. It consists of a hub with rollers

oriented at 45° about the axis of rotation. Mecanum wheel is perfect for tight spaces, since

it enables conventional forward and backward movements as well as side-to-side and even

rotations. The manual robot also uses a 24 V DC motor with a dimension of 80 mm x 80

149