Page 106 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 106

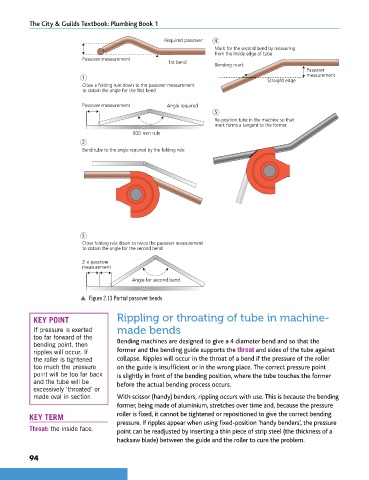

Required passover

Passover measurement

1st bend

1

Close a folding rule down to the passover measurement

to obtain the angle for the first bend

Angle required

Passover measurement

600 mm rule

2

Bend tube to the angle required by the folding rule

3

Close folding rule down to twice the passover measurement

to obtain the angle for the second bend

2 × passover

measurement

The City & Guilds Textbook: Plumbing Book 1 Angle for second bend

Required passover 4

Mark for the second bend by measuring

from the inside edge of tube

Passover measurement

1st bend Bending mark

Passover

measurement

1 Straight edge

Close a folding rule down to the passover measurement

to obtain the angle for the first bend

Passover measurement Angle required

5

Re-position tube in the machine so that

mark forms a tangent to the former

600 mm rule

2

Bend tube to the angle required by the folding rule

3

Close folding rule down to twice the passover measurement

to obtain the angle for the second bend

2 × passover

measurement

Angle for second bend

p Figure 2.13 Partial passover bends

4

Mark for the second bend by measuring

from the inside edge of tube

KEY POINT Rippling or throating of tube in machine-

Bending mark

If pressure is exerted made bends

Passover

too far forward of the Straight edge measurement

bending point, then Bending machines are designed to give a 4 diameter bend and so that the

ripples will occur. If former and the bending guide supports the throat and sides of the tube against

the roller is tightened collapse. Ripples will occur in the throat of a bend if the pressure of the roller

too much the pressure on the guide is insufficient or in the wrong place. The correct pressure point

5

point will be too far back is slightly in front of the bending position, where the tube touches the former

Re-position tube in the machine so that

and the tube will be before the actual bending process occurs.

mark forms a tangent to the former

excessively ‘throated’ or

made oval in section. With scissor (handy) benders, rippling occurs with use. This is because the bending

former, being made of aluminium, stretches over time and, because the pressure

KEY TERM roller is fixed, it cannot be tightened or repositioned to give the correct bending

pressure. If ripples appear when using fixed-position ‘handy benders’, the pressure

Throat: the inside face. point can be readjusted by inserting a thin piece of strip steel (the thickness of a

hacksaw blade) between the guide and the roller to cure the problem.

94

9781510416482.indb 94 29/03/19 8:52 PM