Page 339 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 339

Chapter 5 Cold water systems

● Cisterns should be marked and drilled for pipe connections in accordance

with BS 6700 and all holes drilled with a hole saw. Installation requirements

should be in accordance with the Water Supply (Water Fittings) Regulations.

● Holes and notches in joists must be carried out in line with the building

regulations.

● A water dead leg refers to any pipework that is no longer in use and there is

a risk of the water turning stagnant which could contaminate the system.

These are normally redundant branches and should be removed in order to

prevent this from happening.

Connections to bathroom equipment and other common

components

When connecting bathroom equipment, the manufacturer’s installation

instructions should be referred to. The design of the installation will dictate

the size of the pipe required to deliver the flow rate, but the connection size

to the tap will be dictated by the tap itself (see Table 5.11).

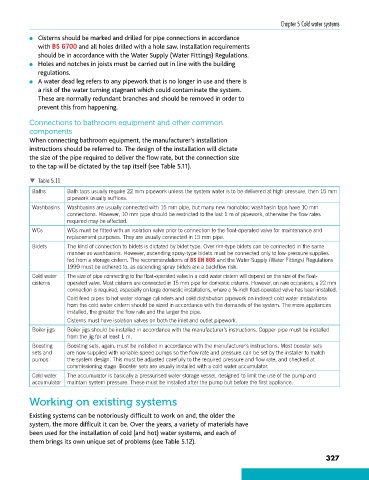

Table 5.11

Baths Bath taps usually require 22 mm pipework unless the system water is to be delivered at high pressure, then 15 mm

pipework usually suffices.

Washbasins Washbasins are usually connected with 15 mm pipe, but many new monobloc washbasin taps have 10 mm

connections. However, 10 mm pipe should be restricted to the last 1 m of pipework, otherwise the flow rates

required may be affected.

WCs WCs must be fitted with an isolation valve prior to connection to the float-operated valve for maintenance and

replacement purposes. They are usually connected in 15 mm pipe.

Bidets The kind of connection to bidets is dictated by bidet type. Over rim-type bidets can be connected in the same

manner as washbasins. However, ascending spray-type bidets must be connected only to low-pressure supplies

fed from a storage cistern. The recommendations of BS EN 806 and the Water Supply (Water Fittings) Regulations

1999 must be adhered to, as ascending spray bidets are a backflow risk.

Cold water The size of pipe connecting to the float-operated valve in a cold water cistern will depend on the size of the float-

cisterns operated valve. Most cisterns are connected in 15 mm pipe for domestic cisterns. However, on rare occasions, a 22 mm

connection is required, especially on large domestic installations, where a ¾-inch float-operated valve has been installed.

Cold feed pipes to hot water storage cylinders and cold distribution pipework on indirect cold water installations

from the cold water cistern should be sized in accordance with the demands of the system. The more appliances

installed, the greater the flow rate and the larger the pipe.

Cisterns must have isolation valves on both the inlet and outlet pipework.

Boiler jigs Boiler jigs should be installed in accordance with the manufacturer’s instructions. Copper pipe must be installed

from the jig for at least 1 m.

Boosting Boosting sets, again, must be installed in accordance with the manufacturer’s instructions. Most booster sets

sets and are now supplied with variable-speed pumps so the flow rate and pressure can be set by the installer to match

pumps the system design. This must be adjusted carefully to the required pressure and flow rate, and checked at

commissioning stage. Booster sets are usually installed with a cold water accumulator.

Cold water The accumulator is basically a pressurised water storage vessel, designed to limit the use of the pump and

accumulator maintain system pressure. These must be installed after the pump but before the first appliance.

Working on existing systems

Existing systems can be notoriously difficult to work on and, the older the

system, the more difficult it can be. Over the years, a variety of materials have

been used for the installation of cold (and hot) water systems, and each of

them brings its own unique set of problems (see Table 5.12).

327

9781510416482.indb 327 29/03/19 8:59 PM