Page 245 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 245

Pumping of Liquids 215

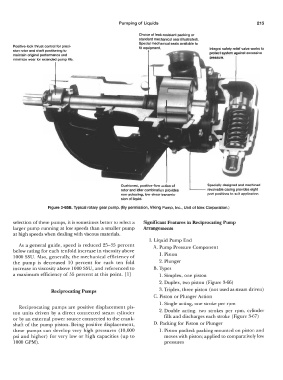

Choice of leak-resistant packing or

standard mechanical seal (illustrated).

Special mechanical seals available to

Positive-lock thrust control for preci- fit equipment.

sion rotor and shaft positioning to Integral safety relief valve works to

protect system against excessive

maintain original perfonnance and pressure.

minimize wear for extended pump life.

Cushioned, positive-flow action of Specially designed and machined

rotor and idler combination provides ....____ revolvable casing provides eight

non-pulsating, low-shear transmis- port positions to suit application.

sion of liquid.

Figure 3-658. Typical rotary gear pump. (By permission, Viking Pump, Inc., Unit of ldex Corporation.)

selection of these pumps, it is sometimes better to select a Significant Features in Reciprocating Pump

larger pump running at low speeds than a smaller pump Arrangements

at high speeds when dealing with viscous materials.

I. Liquid Pump End

As a general guide, speed is reduced 25-35 percent A. Pump Pressure Component

below rating for each tenfold increase in viscosity above

1000 SSU. Also, generally, the mechanical efficiency of I. Piston

the pump is decreased 10 percent for each ten fold 2. Plunger

increase in viscosity above 1000 SSU, and referenced to B. Types

a maximum efficiency of 55 percent at this point. [1] 1. Simplex, one piston

2. Duplex, two piston (Figure 3-66)

3. Triplex, three piston (not used as steam driven)

Reciprocating Pumps

C. Piston or Plunger Action

1. Single acting, one stroke per rpm

Reciprocating pumps are positive displacement pis-

ton units driven by a direct connected steam cylinder 2. Double acting, two strokes per rpm, cylinder

or by an external power source connected to the crank- fills and discharges each stroke (Figure 3-67)

shaft of the pump piston. Being positive displacement, D. Packing for Piston or Plunger

these pumps can develop very high pressures ( 10,000 1. Piston packed: packing mounted on piston and

psi and higher) for very low or high capacities (up to moves with piston; applied to comparatively low

1000 GPM). pressures