Page 246 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 246

216 Applied Process Design for Chemical and Petrochemical Plants

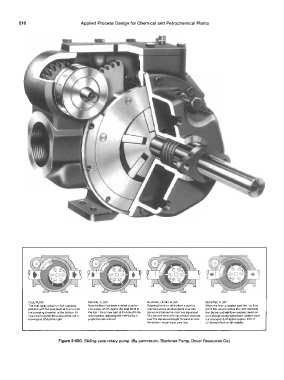

FULL FLOW PARTIAL FLOW NEUTRAL OR NO FLOW REVERSE FLOW

The hner (grey areal rs in full-capacity Now the liner has been rotated counter- Rolahng the liner snn further. a pomt rs When the hner rs rotated past the "no flow"

position with the seal po,nt at the ton and clockwise. which opens the seal pomt al reached where displacement volumes point. the volume above lhe rotor exceeds

!he pumping chamber at the bottom AU lhe lop This allows par1 of lhe liquid lo be above and below the rotor are equahzed lhat below. and net flow reverses d1rect1on

hqurd coming into the pump at the left rs recirculated, reducing the net flow by a This causes as much l!Qu1d to be returned even though pump speed and relation have

moving out of 11 at lhe nght. proportionate amount over the lop as rs brought forward across nol changed 1L1m1led lo approx 30'I, of

the bottom resull+ng m zero flow full forward ttow on all models I

Figure 3-65C. Sliding vane rotary pump. (By permission, Blackmer Pump, Dover Resources Co.)