Page 247 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 247

Pumping of Liquids 217

R, .. o •• ble ttun cl.nt

cou,, P4naftfln! quld1

•«•• to ll"m .... R" ..

Rr,1d nd Iron cradl ..

of Hrnlcircul., Hction.

Hturln 11 li;:::::h .nd

Twin llquld cyllncl1tt m•·

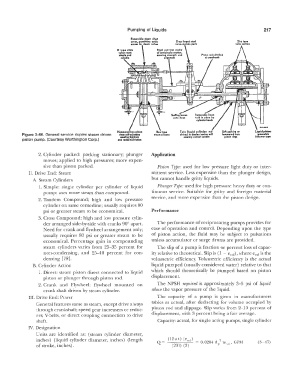

Figure 3-66. General service duplex steam driven cMned IA dwpfu botint •ill

au•ri111 cotnd ccn19f'I

piston pump. (Courtesy Worthington Corp.)

2. Cylinder packed: packing stationary; plunger Application

moves; applied to high pressures; more expen-

sive than piston packed. Piston Type: used for low pressure light duty or inter-

II. Drive End: Steam mittent service. Less expensive than the plunger design,

A. Steam Cylinders but cannot handle gritty liquids.

1. Simple: single cylinder per cylinder of liquid Plunger Type: used for high pressure heavy duty or con-

pump; uses more steam than compound. tinuous service. Suitable for gritty and foreign material

service, and more expensive than the piston design.

2. Tandem Compound; high and low pressure

cylinder on same centerline; usually requires 80

psi or greater steam to be economical. Performance

3. Cross Compound: high and low pressure cylin-

der arranged side-by-side with cranks 90° apart. The performance of reciprocating pumps provides for

Need for crank and flywheel arrangement only; ease of operation and control. Depending upon the type

usually requires 80 psi or greater steam to be of piston action, the fluid may be subject to pulsations

economical. Percentage gain in compounding unless accumulator or surge drums are provided.

steam cylinders varies from 25-35 percent for The slip of a pump is fraction or percent loss of capac-

non-condensing, and 25-40 percent for con- ity relative to theoretical. Slip is (1 - ev 01), where e, 01 is the

densing [] 8]. volumetric efficiency. Volumetric efficiency is the actual

B. Cylinder Action liquid pumped (usually considered water) relative to that

l. Direct: steam piston direct connected to liquid which should theoretically be pumped based on piston

piston or plunger through piston rod. displacement.

2. Crank and Flvwheel: flvwheel mounted on The NPSH required is approximately 3-5 psi of liquid

/ /

crank shaft driven by steam cylinder. above the vapor pressure of the liquid.

III. Drive End: Power The capacity of a pump is given in manufacturers

General features same as steam, except drive always tables as actual, after deducting for volume occupied by

through crankshaft; speed gear increasers or reduc- piston rod and slippage. Slip varies from 2-10 percent of

ers; Vbelts, or direct coupling connection to drive displacement, with 3 percent being a fair average.

shaft. Capacity: actual, for single acting pumps, single cylinder

IV. Designation

Units are identified as: (steam cylinder diameter,

(l2a t) (e"

01)

inches) (liquid cylinder diameter, inches) (length Q= ------'-'- (3- 47)

of stroke, inches). (231) (2) 0.0204 ct/ tevoi' GPM