Page 243 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 243

Pumping of Liquids 213

required submergence. If the water is al l00°F at sea level, used for metering. For specific performance characteris-

approximateiy 17 inches must be added to the 70°F sub- tics of any type consult the appropriate manufacturer.

mergence value [14].

These pumps are low in cost, require small space, and

are self priming.

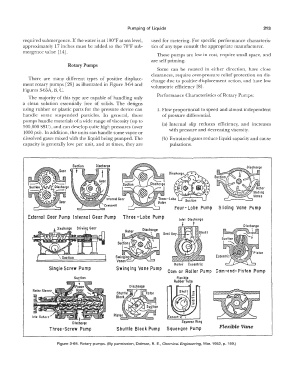

Rotary Pumps

Some can be rotated in either direction, have close

clearances, require over-pressure relief protection on dis-

There are many different types of positive displace- charge due to positive displacement action, and have low

ment rotary pumps [29] as illustrated in Figure 3-64 and volumetric efficiency [8].

Figures 3-65A, B, C.

Performance Characteristics of Rotary Pumps:

The majority of this type are capable of handling only

a clean solution essentially free of solids. The designs

using rubber or plastic parts for the pressure device can 1. Flow proportional to speed and almost independent

handle some suspended particles. In general, these of pressure differential.

pumps handle materials of a wide range of viscosity (up to

500,000 SSU), and can develop quite high pressures ( over (a) Internal slip reduces efficiency, and increases

1000 psi). In addition, the units can handle some vapor or with pressure and decreasing viscosity.

dissolved gases mixed with the liquid being pumped. The (b) Entrained gases reduce liquid capacity and cause

capacity is generally low per unit, and at times, they are pulsations.

Suction

Four-Lobe Pump Sliding Vane Pump

External Gear Pump Internal Gear Pump Three -Lobe Pump Inlet Discharge

i t Discharge

Drivi;g Gear fil__�,0/-� I I

��

Single Screw Pu mp Swinging Vane Pump

Com or Roller Pump Cam-and-Piston Pump

Su�tion Flexible

Rubber Tu�e

·, t

Discharge

Three-Screw Pump Shuttle Block Pump Squeegee Pump Flexible Vane

Figure 3-64. Rotary pumps. (By permission, Dolman, R. E., Chemical Engineering, Mar. 1952, p. 159.)