Page 394 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 394

362 Applied Process Design for Chemical and Petrochemical Plants

Example 6-4: Steam Air Mixture Temperature in Ejector 3. The 70°F air equivalent correcting for temperature

is found as previously described, using the air curve

Steam used to draw air out of a vessel is: of Figure 6-17.

240 psig (255 psia) @ 440°F total temp

This is: 440 - 402 sat temp = 38 superheat Example 6-5: Actual Capacity For Process Vapor Plus

Temp of air from vessel: 75°F N on-Condensable

Steam flow: 475 lbs/hr

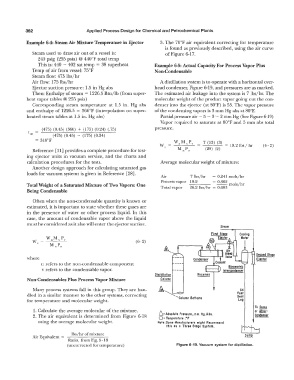

Air flow: 175 lbs/hr A distillation system is to operate with a horizontal over-

Ejector suction pressure: 1.5 in Hg abs head condenser, Figure 6-19, and pressures are as marked.

Then: Enthalpy of steam = 1226.5 Btu/lb (from super- The estimated air leakage into the system is 7 lbs/hr. The

heat vapor tables @ 255 psia) molecular weight of the product vapor going out the con-

Corresponding steam temperature at 1.5 in. Hg abs denser into the ejector (at S0°F) is 53. The vapor pressure

and enthalpy of 1226.5 = 366°F (interpolation on super- of the condensing vapors is 3 mm Hg abs at 80°F.

heated steam tables at 1.5 in. Hg abs) Partial pressure air= 5 - 3 = 2 mm Hg (See Figure 6-19)

Vapor required to saturate at 80°F and 5 mm abs total

t = (475) (0.45) (366) + (175) (0.24) (.75) pressure.

rn ( 475) (0.45) + (175) (0.24)

= 318° F

3

w 7 53 ) ( ) = 19. 2 lbs I hr (6- 2)

(

Reference [11] provides a complete procedure for test- \' (29) (2)

ing ejector units in vacuum service, and the charts and

calculation procedures for the tests. Average molecular weight of mixture:

Another design approach for calculating saturated gas

loads for vacuum systems is given in Reference [28].

Air 7 lbs/hr = 0.241 mols/hr

Process vapor 19.2 = 0.362

--mos

Total Weight of a Saturated Mixture of Two Vapors: One Total vapor 26.2 lbs/hr = 0.603 1 /h r

Being Condensable

Often when the non-condensable quantity is known or

estimated, it is important to state whether these gases are

in the presence of water or other process liquid. In this

case, the amount of condensable vapor above the liquid

must be considered as it also will enter the ejector suction.

Steam

(6-2)

Second Stag�

where �.!.£!2!

n refers to the non-condensable component

v refers to the condensable vapor.

Distillation

Non-Condensables Plus Process Vapor Mixture Column

Many process systems fall in this group. They are han- 34

Feet

dled in a similar manner to the other systems, correcting �Column Bottoms Seal

for temperature and molecular weight. Leo

To Sume.

l. Calculate the average molecular of the mixture. or After-

2. The air equivalent is determined from Figure 6-18 6= Absolute Pressure, mm. Hg. Abs. Condenser

O= Temperature , °F

using the average molecular weight. Note :Some Manufacturers might Recommend

this as a Three Stage Sy&tem.

lbs/hr of mixture

Air Equivalenl =

Ratio, from Fig. 6- 18

(uncorrected for temperature) Figure 6-19. Vacuum system for distillation.