Page 389 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 389

400

300

200

:----+-·

100

90

80

70

60

50

40

30

20

10

9

... 8

::, 7

0 6

"'

.J:> 5

<t

a, 4

�

E 3

E

- 2

...

::,

-

"'

"' ...

0..

c:

0 1.0

- .9

'-'

:::,

(/) .8

.7

.6

.5

.4

.3

.2

.01 L....J..��-'-..;,_;c.....J.....l-.1..-1--'-..J.......1-J....-'-'--L.�'-'--'--'--'-'-""---'--'-�'-'--'-.1..-...1.-'-...L.....J--l...--"-'----'--'--'---'-...L.....J-'---"-�--'--'--'--'-..J.......1--l......._,

0 i2 24 36 48 60 72 84 96 108 120

Capacity - lbs. Air per hour

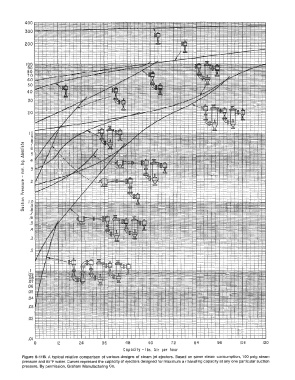

Figure 6-118. A typical relative comparison of various designs of steam jet ejectors. Based on same steam consumption, 100 psig steam

pressure and 85°F water. Curves represent the capacity of ejectors designed for maximum air handling capacity at any one particular suction

pressure. By permission, Graham Manufacturing Co.