Page 403 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 403

Ejectors and Mechanical Vacuum Systems 371

�-00------ INLET

MOTIVE STCAM

IOOSTU UECTOlt

...

•

:!!•

.. o

... 1 -- INTElt • COND •

::, <>

cw

z ..

...

DIIAIN LOOP

IIHAUIT

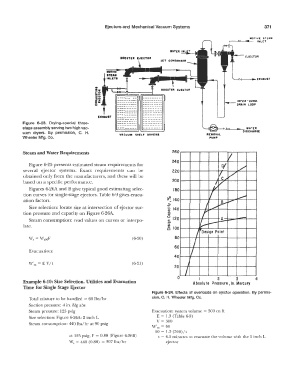

Figure 6-23. Drying-special three-

stage assembly serving two high vac-

uum dryers. E,y permission, C. H. vacuu• SHELF DltYEltl ltEMOYAL

Wheeler Mfg. Co. PUMP

Steam and Water Requirements 260

I

240

Figure 6-25 presents estimated steam requirements for o/

several ejector systems. Exact requirements can be 220 /

obtained only from the manufacturers, and these will be l v

C..;

based on a specific performance. 200 I v

Figures 6-26A and B give typical good estimating selec- 180 I/

tion curves for single-stage ejectors. Table 6-9 gives evacu- r _.,,.-

-

ation factors. � 160 y

......--

>,

Size selection: locate size at intersection of ejector suc- 'g 140 I ./

tion pressure and capacity on Figure 6-26A. Q. r -

0

.J-

Steam consumption: read values on curves or interpo- � 120 I,- --

""

late. ·;;;

� 100

J Design Po int

(6-20) 80 I

60

Evacuation: I

40

W'm=EV/t (6-21) J

20

I

0 I 2 3 4

Example 6-10: Size Selection. Utilities and Evacuation Absolute Pressure, In. Mercury

Time for Single Stage Ejector

Figure 6-24. Effects of overloads on ejector operation. By permis-

Total mixture to be handled = 60 lbs/hr sion, C. H. Wheeler Mfg. Co.

Suction pressure: 4 in. Hg abs

Steam pressure: 125 psig Evacuation: system volume = 300 cu ft

Size selection: Figure 6-26A: 2 inch L E = 1.3 (Table 6-9)

V = 300

Steam consumption: 440 lbs/hr at 90 psig

\V'm = 60

60 = 1.3 (300)/t

at 125 psig, F = 0.88 (Figure 6-26B) t = 6.5 minutes lo evacuate the volume with the 2-inch L

W, = 440 (0.88) = 397 lbs/hr ejector