Page 404 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 404

372 Applied Process Design for Chemical and Petrochemical Plants

Ejector Suction Pressure, mm. Hg. Abs.

100 --===:::::J==::r:::r::::::i::r:1::::r:i::::i:::====:i::::::J::::::J � ;::J::r:r: � oto1====0jo=2=0jot3:::to=ot5rojoj1joj1=====0E2:::::oi3:::::J=oi5:rot1rii 1 0

1- �+-f-Plj---+--+-+-+-+-Hl+l---+--�-+-+-l--�-+-l l,000

I

70

1--,, __ ....1....._�--4---4---l--+-Jl..-l--l----4--.j.._.--i---l--l..-l--'�' " ........i-1-� ' ---'=--- 1 -.l.._1,-+-+-+4-+-l---+--�-+---l--+--l--l--l--l700

' ,

Four Stage ,cl6)

, Six Stage c (6)

50 ,_ /100%Air lwo Stage,nc(3)(5) r--, " 500

j \ Three Stage, Borometri· � <J..\ c � r-,

30 'lntercondensers(5) .... .,..,"- �"- r,.:- 300 ...

1--t...... ) I I I II II '% � , 0- 1 -....... ...

r-,

Single Stog_e, "' .

'"

20 I ---......... V 1\.,,100% Air in Mixture f\. � " I A' nc (1)(2 )15) +..: �� ...- .' ,1--+-J�++++---+---1-l---4---+-+-l-+-I 200-:

q-? ��

\ \ ·

�

...

e I'\ � � I'._ I � I\ Five Stage, c (6) ::::E

..

�

= \ " r'\r,.. r-, r,.., �'$ � " <

� 10 " '- ,---l----1f--l--4- � +-1- � ---1-----1"1-1,Four Stage ,c (6) 100 ;e

...

'

"

E

\

�

< 7 l------1---+-���'>i-1-+-P,,..o;:--'�..,....-+-l-+-1--P..i-l����--�-+--l---+4-�' .�+-' ... ......._:-----+�---+-lr,+-+-+-+-+-1-l 70 ..

...

"""'

........_

---.

,s I'\ "

..

' 5 ' I'll'- i"",.NL.-IQ9%�ir'\_ \_ f '-� '!'\. 50 iii

e

.,;

...

vi � V � tur· � � . � � 2\.---+--+-+-+--+-+4j,1n-1--......,_, � ' All Curv:S �-., .&:,

e

.,; 3 "r0-. 30 ,::,

.&:, "�10%A�........._ [f. Two Stage, ,, 11 far 100% Air

I ........._ in Mixtur)'""" ,

Barometric

..., M 2 1----4--+--l--l--+-H-+-l-----".;.:-.........:..:.:;:=.=+ � 1-l'-..."""4 � tercondenser (4)(5) I'....,"\ ,"\ � 20 .,,.

'"

...

...

a,

"�

.,,.

·5 � ..... t-...t-...t,.,.- 10%Air in I�" � �' a:

e

...

c:,

a: 1 'r-......._ "' Mixture I ,, �

e 1.0 10 en

...

c:, t----+--+--+-+-+-t-i-+-t-----+--+--+-+-+-+-t-+t---+- , -+--+--+-+-t-+++---1-----11--+-+-..P.�-

vi 0.7 t-----+--+---+--+1 Steam Pressure = JOO psig.

t-----+--+---+--+1 Condensing Curves based on 85° F Water, Correction is < 10% for 70 • F.

0.5 1-----+--+---+--+1 For Air Quantities between 10% and 100%, Requirements Located by Proportion. 1-1---4---1---1---+.4-1--+-<

1----+---+--l--H Mixtures Assumed to be Air and Water Vapor, if other Vapors or Gases Convert

to Air Equivalent.

0.3 1-----4----1---+.---+-1 c =Condensing, with Barometric lntercondenser.

nc = Non-Condensing.

0.2

2 3 5 7 10 20 30 50 70 100 200 300 500 700 1,000

Ejector Suction Pressure, mm. Hg. Abs.

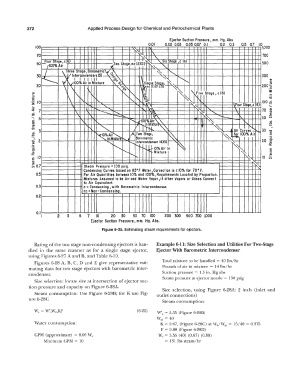

Figure 6-25. Estimating steam requirements for ejectors.

Rating of the two stage non-condensing ejectors is han- Example 6-11: Size Selection and Utilities For Two-Stage

dled in the same manner as for a single stage ejector, Ejector With Barometric Intercondenser

using Figures 6-27 A and B, and Table 6-10.

Figures 6-28 A, B, C, D and E give representative esti- Total mixture to be handled = 40 lbs/hr

mating data for two stage ejectors with barometric inter- Pounds of air in mixture = 14 lbs/hr

condenser. Suction pressure = 1.5 in. Hg abs

Steam pressure at ejector nozzle = 150 psig

Size selection: locate size at intersection of ejector suc-

tion pressure and capacity on Figure 6-28A.

Size selection, using Figure 6-28A: 2 inch (inlet and

Steam consumption: Use Figure 6-28B; for Kuse Fig- outlet connections)

ure 6-28C

Steam consumption:

(6-22)

W', = 5.55 (Figure 6-288)

'\<\\n = 40

Water consumption: K == 0.67, (Figure 6-28C) at W /vVm = 15/40 = 0.375

3

F == 0.88 (Figure 6-28D)

GPM (approximate) = 0.06 W, w, == 5.55 ( 40) (0.67) (0.88)

Minimum GPM = 10 == 131 lbs steam/hr