Page 409 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 409

Ejectors and Mechanical Vacuum Systems 377

SPE;.C, D\"i'G, NO.

A.

Job No, --------------

Page of Pag<-s

B/M No. Unit Price

STEAM EJECTOR SPECIFICATIONS No. Uni ts I

Item No.

PERFORMANCE

-

Make -- Type

Servi ce Condenser: D Borometri c OSurface

No. of Stages No, of Ejectors per Stage --

Suet. Pr e s s MM HgAbs. Suet. Temp OF Max. Di sch. Press MM HgAbs.

Ste cm: Min. Pre!.s PSIA. Temp. __ oF Ouality %

Water! Sou re" Mox. Press _____ PSIA. Mox. Temp. OF

Vol. of Evccuated System Cu. Ft.

Expected Air Leakage L bs/H,.

Max, Evacuating Time Min.

Ejector Load -- Lbs/Hr. -- -- Mol. Wt. - _Cp, BTU/Lb-CF - __ Latent Ht., BTU/Lb. -

Condensobles

Nc n- Condensobles

---

DESIGN I

-·

1 st. Stage 2nd. Stage 3rd. Stage 4th. Stage 5th Stage

P rope I ling Steam, L.bs/H,. - I

Sfecm: !nlet Size --

Press. Class & Facing �----

Water, GPM

- -·· -- i--------------. -- �-- --

Water .'\ T, ° F -

Water: Inlet Size

Press. Class & Facing

Water: Exit Size

� Pre.ss. Class & Facing

� hamber Pr e s s, MM HgABS. .

Suet. Chamber Temp.° F

Condensers: Pre .. Inter .. After I

Barometric: No.Contact Stages I

Sur lc ce: Outside Tube Area Sq. F,. I

MATERIALS OF CONSTRUCTION

Ejector: Steam Chest Steam Nozzles

Di Huser: Inlet Dischorge Su ct. Chamber

1st. Stage Suet. Chamber Inlet (Siz:e x Pr. Cl. x Facing} x x

Barometric Condens.er: Shell Baflleo • Nozzles

I Surface Condenser: Shell x x Heed Material

Tubes (0.0. x !lWG x L)

Tube Sheet Baffles

Steam Strainer Shut Off Valves

�

c

n

3 " �

REMARKS .

�

n

Toil Pipes Furnished by

Interconnecting Piping by .

0

�

0

�

r

�

� I Chk'd. I App. IRev. _ ]S __ t:__ z c

Date I "' "

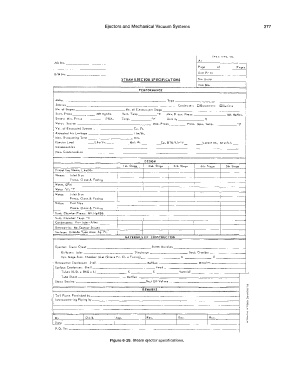

Figure 6-29. Steam ejector specifications.