Page 427 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 427

Ejectors and Mechanical Vacuum Systems 393

SEAUl!Cl

FLUID OUT

SU.UNG

FLUIDlH

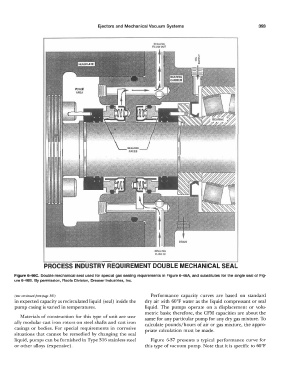

PROCESS INDUSTRY REQUIREMENT DOUBLE MECHANICAL SEAL

Figure 6-46C. Double mechanical seal used for special gas sealing requirements in Figure 6-46A, and substitutes for the single seal of Fig-

ure 6-468. By permission, Roots Division, Dresser Industries, Inc.

(uxt conli11ued from page 385) Performance capacity curves are based on standard

in expected capacity as recirculated liquid (seal) inside the dry air with 60°F water as the liquid compressant or seal

pump casing is varied in temperatures. liquid. The pumps operate on a displacement or volu-

metric basis; therefore, the CFM capacities are about the

Materials of construction for this type of unit are usu- same for any particular pump for any dry gas mixture. To

ally modular cast iron rotors on steel shafts and cast iron calculate pounds/hours of air or gas mixture, the appro-

casings or bodies. For special requirements in corrosive priate calculation must be made.

situations that cannot be remedied by changing the seal

liquid, pumps can be furnished in Type 316 stainless steel Figure 6-37 presents a typical performance curve for

or other alloys (expensive). this type of vacuum pump. Note that it is specific to 60°F