Page 435 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 435

Process Safety and Pressure-Relieving Devices 401

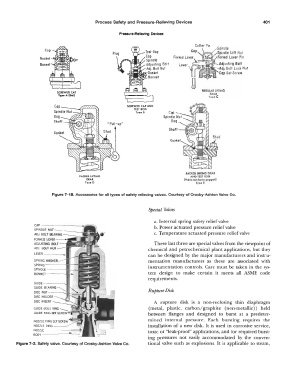

Pr988ure-Rellevlng Devices

Spindle

Test Gag Spindle Lift Nu!

Cap Forked Lever Pin

.....,._,,,,,, Spindle ���

Adjusting Bolt Lever Adjusting Boll

Adj. Bolt Nut Adj. Ball Lock Nut

Gasket Cap Set Screw

Bor,net

REGULAR llftlMG

SCREWED CAP GEAR

Type A (Std.) type C

SCREWED CAP AND

TEST ROD

Type B

PACKED LIFTING GEAR

PACKED LIFTING ANDTESTROO

GEAR (Voi...e not ohowo uo;;..t)

Type D Typ• E

Figure 7-18. Accessories for all types of safety relieving valves. Courtesy of Crosby-Ashton Valve Co.

Special Valves-

a. Internal spring safety relief valve

CAP --------�..;. b. Power actuated pressure relief valve

SPINDLE NUT

ADJ BOLT BEARING c. Temperature actuated pressure relief valve

These last three are special valves from the viewpoint of

chemical and petrochemical plant applications, but they

can be designed by the major manufacturers and instru-

mentation manufacturers as these are associated with

instrumentation controls. Care must be taken in the sys-

tem design to make certain it meets all ASME code

requirements.

Rupture Disk

DISC NUT----..._loi-k-·-""

DISC HOLDER

DISC INSERT A rupture disk is a non-reclosing thin diaphragm

GUIDE (ADJ) RING (metal, plastic, carbon/graphite (non-metallic)) held

between flanges and designed to burst at a predeter-

mined internal pressure. Each bursting requires the

NOZZLE RING ----- installation of a new disk. It is used in corrosive service,

....

NOZZLE------- toxic or "leak-proof' applications, and for required burst-

BODY-------.

ing pressures not easily accommodated by the conven-

Figure 7-2. Safety valve. Courtesy of Crosby-Ashton Valve Co. tional valve such as explosions. It is applicable to steam,