Page 439 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 439

Process Safety and Pressure-Relieving Devices 405

Burst Pressure: the inlet static pressure at which a rup- plate) (see Par. UG-A22) but exclusive of any corrosion

ture disk pressure-relieving device functions or opens to allowance or other thickness allowances for loadings (see

release internal pressure. ASME Par.-UG-22) on vessels other than pressure (for

example, extreme wind loadings for tall vessels). The

Design Pressure: the pressure used in the vessel design to

establish the minimum code permissible thickness for

containing the pressure.

Maximum Allotuable Working Pressure (MAWP): the maxi-

mum pressure pounds per square inch gauge permissible

at the top of a completed vessel in its operating position

for a specific designated temperature corresponding to

the MAWP pressure. This pressure is calculated in accor-

dance with the ASME code (Par. UG-98) [I] for all parts

or elements of the vessel using closest next larger to cal-

culated value nominal thickness ( closest standard for steel

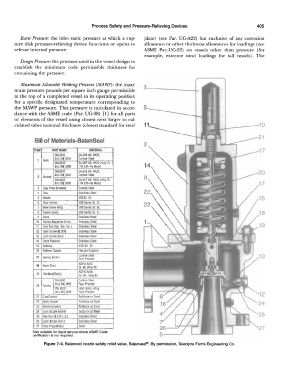

em of Materials-BalanSeal

rrBI MllT MAME lllmlllAL

26( )910 s.\-218 GR. �6.

!IIIIJ 26( )826 Cart>on S!ffl

1 Bod';

26( )832 sP..217 GR. WC6, Alloy SL

lllru 26( )836 (1V, ca-w Moly)

26( )810 SA-21& GR. wca.

mru 26( )B26 Carlloo Steel

2 Bonnet

26( )832 SA-2T7 GR. WC6. Alloy St.

Hlrll 26( )836 (1\11 CR-YI Mel\/)

3 Clp.P\aJn� Carbon S!HI

• [Jisc S!ilnlns Sb!ef

5 Nonie 316 St. SL

6 [),s,: Holdv 300 Senes SI. St.

7 Blow Down Flin� 300 Senn St. St.

! SI-Guide 300 Sertllll St. St.

9 Slllm StllnllH SIMI

10 SPllng hl11Jstino Screw Stalnless Sl!!JI

11 Jim Nu! (Spr. Adj, Ser) Stainless Stoel

12 IJJck ScrM (S.U R) Slllinlas SINI

,� LDl:kScrNSDJd Stal,i1%s S!Mt

13

Stirn Retainer

Stainless Steel

15 Bellows 316l St. SL

16 S.llows Gasqt Fll!x, ble Graplllte

Camon Steil

17 St>nnq Bultlln Aust Prooted

ASTM Al9J --

18 Sod)' Stud Gr. 87, Moy St

ASTM A194

19 Ho Nut (Bo�} Gr 2H, Alloy St.

26( )810 Carbon Steel

!liru 26( 1816 Rusi Prool!d

20 Spnnq

26( )820 Hfqn Temp. Alloy

!liru 26( )636 Au!I Proofed

21 C:i.p Gasket Soft lrcn or St•el

22 lkxfy G..sllrt SllN Iron or Steel

23 Bonnel G ul<et Solt Iron or Steel

24 Loek ScrN Gasket Soft Iron or Steel

2!i Hex Nul {B.O.RLS.) Stainlm S1eel

26 Lock Screw (0 H.) Suinleu St&el

'1T Pip, Plug U!ody) Ste&I ·-

Also suitable for liquid service where ASME Code

certification is not required.

Figure 7-4. Balanced nozzle safety relief valve, Balanseal®. By pennission, Teledyne Farris Engineering Co.