Page 440 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 440

406 Applied Process Design for Chemical and Petrochemical Plants

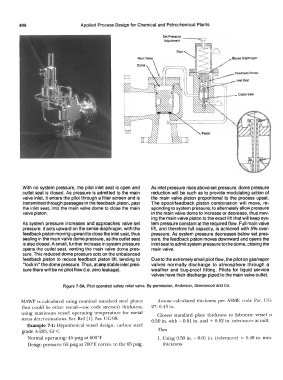

With no system pressure, the pilot inlet seat is open and As inlet pressure rises above set pressure, dome pressure

outlet seat is closed. As pressure is admitted to the main reduction will be such as to provide modulating action of

valve inlet, it enters the pilot through a filter screen and is the main valve piston proportional to the process upset.

transmitted through passages in the feedback piston, past The spool/feedback piston combination will move, re-

the inlet seat, into the main valve dome to close the main sponding to system pressure, to alternately allow pressure

valve piston. in the main valve dome to increase or decrease, thus mov-

ing the main valve piston to the exact lift that will keep sys-

As system pressure increases and approaches valve set tem pressure constant at the required flow. Full main valve

pressure, it acts upward on the sense diaphragm, with the lift, and therefore full capacity, is achieved with 5% over-

feedback piston moving upward to close the inlet ssat, thus pressure. As system pressure decreases below set pres-

sealing in the main valve dome pressure, as the outlet seat sure, the feedback piston moves downward and opens the

is also closed. A small, further increase in system pressure inlet seat to admit system pressure to the dome, closing the

opens the outlet seat, venting the main valve dome pres- main valve.

sure. This reduced dome pressure acts on the unbalanced

feedback piston to reduce feedback piston lift, tending to Due to the extremely small pilot flow, the pilot on gas/vapor

"lock in" the dome pressure. Thus, at any stable inlet pres- valves normally discharge to atmosphere through a

sure there will be no pilot flow (i.e. zero leakage). weather and bug-proof fitting. Pilots for liquid service

valves have their discharge piped to the main valve outlet.

Figure 7-5A. Pilot operated safety relief valve. By permission, Anderson, Greenwood and Co.

MAWP is calculated using nominal standard steel plates Assume calculated thickness per ASME code Par. UG-

(but could be other metal-use code stresses) thickness, 27: 0.43 in.

using maximum vessel operating temperature for metal Closest standard plate thickness to fabricate vessel is

stress determinations. See Ref [l] Par. UG-98. 0.50 in. with - 0.01 in. and + 0.02 in. tolerances at mill.

Example 7-l: Hypothetical vessel design, carbon steel

grade A-285, Gr C Then

Normal operating: 45 psig at 600°F 1. Using 0.50 in. - 0.01 in. (tolerance) = 0.49 in. min.

Design pressure: 65 psig at 700°F corres. to the 65 psig. thickness.