Page 454 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 454

420 Applied Process Design for Chemical and Petrochemical Plants

tification of the metallurgy (if metal) or other properties

if graphite or plastic, and the disk must be guaranteed by

the manufacturer to burst within 5% (±) of the specified

bursting pressure at the rated temperature. - ANSI flange

Std

The connection nozzle holding the disk must have a

net cross-sectional area no less than that required for the

design rated conditions of the disk.

The certification of disk performance is to be based on

actual bursting tests of two or more disks from a lot of the

same material of the exact same size as the disk to be sold

by the manufacturer. The holder for the test disks must be

identical to the design, dimensions, etc., for the disk ,---,,------ Optional TFE liner blocks

being certified. (See details ASME code, Par. UG-127 [l]). water and dirt from disks

in open vents.

Pressure Settings and Design Basis

Unfired steam boilers, i.e., nominally termed waste heat

boilers or, heat exchangers, which generate steam by heat

interchange with other fluids (See ASME code [I] Par. U-

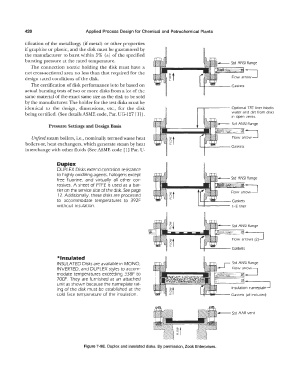

Duplex

DUPLEX Disks extend corrosion resistance

to highly oxidizing agents. halogens except

Std

free fluorine, and virtually all other cor- - ANSI flange

rosives. A sheet of PTFE is used as a bar-

rier on the service side of the disk. See page

12. Additionally. these disks are processed

to accommodate temperatures to 392F L.....H-=---Gaskets

without insulation. L--1'----- TFE liner

- ANSI flange

Std

"����-··· !J: • J

Flow arrows (2)

*Insulated

INSULATED Disks are available in MONO, g:::;:;��s

INVERTED. and DUPLEX styles to accom-

modate temperatures exceeding 338F to

700F. They are furnished as an attached -!. � ..

unit as shown because the nameplate rat- F-----1-n- s u- l a-t � i on J

ing of the disk must be established at the nameplate

cold face temperature of the insulation. 4!.....::��-- Gaskets (all included)

Std AAR vent

-

Figure 7-9E. Duplex and insulated disks. By permission, Zook Enterprises.