Page 303 - REPOWER REFERENCE GUIDE (2020)

P. 303

Engine Alignment

NOTICE

Hot spots in exhaust hoses can damage hoses and cause leaks. Ensure that discharge water from the exhaust elbow flows

without restriction through all hoses and fittings.

26. Align the exhaust tubes.

Typical

a - Exhaust tube

b - Intermediate exhaust elbow

b

a

56296

IMPORTANT: Exhaust hoses and tubes must be secured at each connection with at least two hose clamps.

27. Securely tighten all exhaust hose or exhaust tube clamps.

Description Nm lb‑in. lb‑ft

Tridon® hose clamp (exhaust tube) 4–4.7 35.4–41.6 –

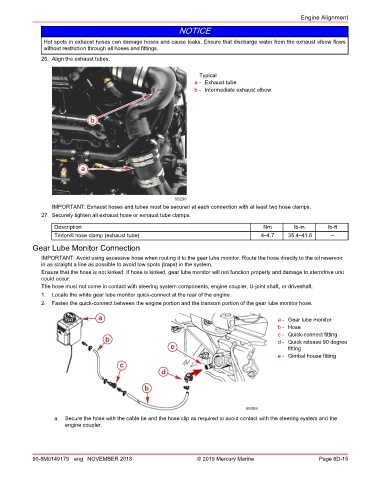

Gear Lube Monitor Connection

IMPORTANT: Avoid using excessive hose when routing it to the gear lube monitor. Route the hose directly to the oil reservoir

in as straight a line as possible to avoid low spots (traps) in the system.

Ensure that the hose is not kinked. If hose is kinked, gear lube monitor will not function properly and damage to sterndrive unit

could occur.

The hose must not come in contact with steering system components, engine coupler, U‑joint shaft, or driveshaft.

1. Locate the white gear lube monitor quick‑connect at the rear of the engine.

2. Fasten the quick‑connect between the engine portion and the transom portion of the gear lube monitor hose.

a a - Gear lube monitor

b - Hose

c - Quick‑connect fitting

b d - Quick release 90 degree

e fitting

e - Gimbal house fitting

c

d

b

68088

a. Secure the hose with the cable tie and the hose clip as required to avoid contact with the steering system and the

engine coupler.

90-8M0149179 eng NOVEMBER 2018 © 2019 Mercury Marine Page 8D-15