Page 329 - Fluid Fitting 2018_extended

P. 329

HIGH QUALITY PRODUCTS EXCELLENCE IN SERVICE

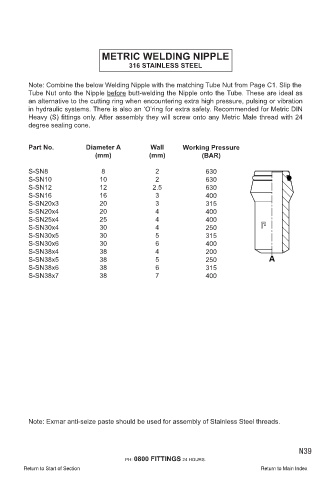

METRIC WELDING NIPPLE

316 STAINLESS STEEL

Note: Combine the below Welding Nipple with the matching Tube Nut from Page C1. Slip the

Tube Nut onto the Nipple before butt-welding the Nipple onto the Tube. These are ideal as

an alternative to the cutting ring when encountering extra high pressure, pulsing or vibration

in hydraulic systems. There is also an ‘O’ring for extra safety. Recommended for Metric DIN

Heavy (S) fittings only. After assembly they will screw onto any Metric Male thread with 24

degree sealing cone.

Part No. Diameter A Wall Working Pressure

(mm) (mm) (BAR)

S-SN8 8 2 630

S-SN10 10 2 630

S-SN12 12 2.5 630

S-SN16 16 3 400

S-SN20x3 20 3 315

S-SN20x4 20 4 400

S-SN25x4 25 4 400

S-SN30x4 30 4 250

S-SN30x5 30 5 315

S-SN30x6 30 6 400

S-SN38x4 38 4 200

S-SN38x5 38 5 250

S-SN38x6 38 6 315

S-SN38x7 38 7 400

Note: Exmar anti-seize paste should be used for assembly of Stainless Steel threads.

PH: 0800 FITTINGS 24 HOURS. N37

PAGE C37 N39

PH: 0800 FITTINGS 24 HOURS.

Return to Start of Section Return to Main Index