Page 137 - Basic Principles of Textile Coloration

P. 137

126 PROTEIN FIBRES

NH CO(CH2)4 CONH (CH2)2 NH (CH2)2 NH CO (CH2)4 Polyamide

n

+ CH2 CH CH2Cl

O

(CH2)2 N (CH2)2 (CH2)2 N (CH2)2

CH2 CH2

CH OH CH O

CH2

CH2Cl

(CH2)2 N (CH2)2 H

(CH2)2 N (CH2)2

H2C CH2

CH2

CH CH OH

CH2OH Hydrolysis product

OH Hercosett polymer

N CH2 CH CH2 S CH2 Wool N CH2 CH CH2 NH Wool

OH OH

Polymer fixed to a wool thiol group Polymer fixed to a wool amino group

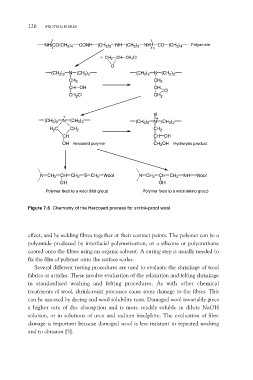

Figure 7.6 Chemistry of the Hercosett process for shrink-proof wool

effect, and by welding fibres together at their contact points. The polymer can be a

polyamide produced by interfacial polymerisation, or a silicone or polyurethane

coated onto the fibres using an organic solvent. A curing step is usually needed to

fix the film of polymer onto the surface scales.

Several different testing procedures are used to evaluate the shrinkage of wool

fabrics or articles. These involve evaluation of the relaxation and felting shrinkage

in standardised washing and felting procedures. As with other chemical

treatments of wool, shrink-resist processes cause some damage to the fibres. This

can be assessed by dyeing and wool solubility tests. Damaged wool invariably gives

a higher rate of dye absorption and is more readily soluble in dilute NaOH

solution, or in solutions of urea and sodium bisulphite. The evaluation of fibre

damage is important because damaged wool is less resistant to repeated washing

and to abrasion [5].