Page 222 - Basic Principles of Textile Coloration

P. 222

DYEING KINETICS 211

through the liquid boundary layer equals the rate of diffusion from the interface

into the fibre. If the rate of diffusion of the dye into the fibre is low, this will

control the overall rate of dyeing and the boundary layer concentration gradient

may be negligible. If, however, diffusion of dye in the fibre is faster, the rate of

solution transport to the fibre surface may not be fast enough to maintain dye

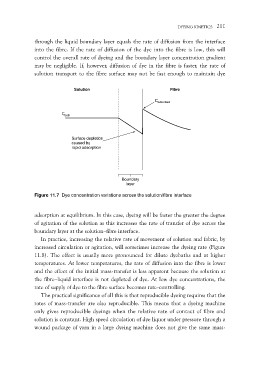

Solution Fibre

Cbath Cadsorbed

Surface depletion

caused by

rapid adsorption

Boundary

layer

Figure 11.7 Dye concentration variations across the solution/fibre interface

adsorption at equilibrium. In this case, dyeing will be faster the greater the degree

of agitation of the solution as this increases the rate of transfer of dye across the

boundary layer at the solution–fibre interface.

In practice, increasing the relative rate of movement of solution and fabric, by

increased circulation or agitation, will sometimes increase the dyeing rate (Figure

11.8). The effect is usually more pronounced for dilute dyebaths and at higher

temperatures. At lower temperatures, the rate of diffusion into the fibre is lower

and the effect of the initial mass-transfer is less apparent because the solution at

the fibre–liquid interface is not depleted of dye. At low dye concentrations, the

rate of supply of dye to the fibre surface becomes rate-controlling.

The practical significance of all this is that reproducible dyeing requires that the

rates of mass-transfer are also reproducible. This means that a dyeing machine

only gives reproducible dyeings when the relative rate of contact of fibre and

solution is constant. High speed circulation of dye liquor under pressure through a

wound package of yarn in a large dyeing machine does not give the same mass-