Page 323 - Basic Principles of Textile Coloration

P. 323

312 DISPERSE DYES

SO3

CH3O OH HC OCH3

CH2 CH OH

(a) HO SO3 OH Glucose ring

CH2CO2H O CH CH OCH3

CH3O

OC O OCH3

CH3O CH OH

H HOCH2 CH OCH3

CH3 CH CH3 CH2 OH

CH2 CH CH SO3

(b) CH3 CH CH3 CH2 CH3 CH CH3

CH2 CH2 CH3 CH2

SO3 CH SO3

CH3

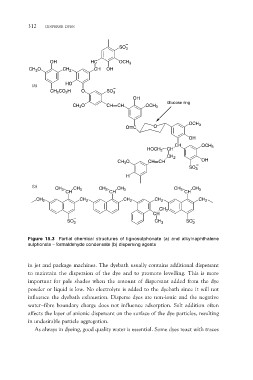

Figure 15.3 Partial chemical structures of lignosulphonate (a) and alkylnaphthalene

sulphonate – formaldehyde condensate (b) dispersing agents

in jet and package machines. The dyebath usually contains additional dispersant

to maintain the dispersion of the dye and to promote levelling. This is more

important for pale shades when the amount of dispersant added from the dye

powder or liquid is low. No electrolyte is added to the dyebath since it will not

influence the dyebath exhaustion. Disperse dyes are non-ionic and the negative

water–fibre boundary charge does not influence adsorption. Salt addition often

affects the layer of anionic dispersant on the surface of the dye particles, resulting

in undesirable particle aggregation.

As always in dyeing, good quality water is essential. Some dyes react with traces