Page 70 - Basic Principles of Textile Coloration

P. 70

POLYESTERS 59

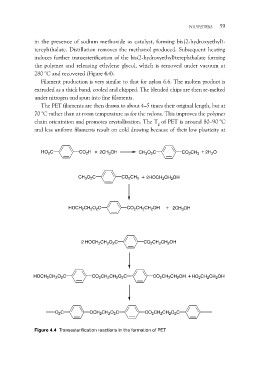

in the presence of sodium methoxide as catalyst, forming bis(2-hydroxyethyl)-

terephthalate. Distillation removes the methanol produced. Subsequent heating

induces further transesterification of the bis(2-hydroxyethyl)terephthalate forming

the polymer and releasing ethylene glycol, which is removed under vacuum at

280 °C and recovered (Figure 4.4).

Filament production is very similar to that for nylon 6.6. The molten product is

extruded as a thick band, cooled and chipped. The blended chips are then re-melted

under nitrogen and spun into fine filaments.

The PET filaments are then drawn to about 4–5 times their original length, but at

70 °C rather than at room temperature as for the nylons. This improves the polymer

chain orientation and promotes crystallisation. The Tg of PET is around 80–90 °C

and less uniform filaments result on cold drawing because of their low plasticity at

HO2C CO2H + 2CH3OH CH3O2C CO2CH3 + 2H2O

CH3O2C CO2CH3 + 2HOCH2CH2OH

HOCH2CH2O2C CO2CH2CH2OH + 2CH3OH

2 HOCH2CH2O2C CO2CH2CH2OH

HOCH2CH2O2C CO2CH2CH2O2C CO2CH2CH2OH +HO2CH2CH2OH

O2C OCH2CH2O2C CO2CH2CH2O2C

Figure 4.4 Transesterification reactions in the formation of PET