Page 75 - Basic Principles of Textile Coloration

P. 75

64 SYNTHETIC FIBRES

As outlined in Section 4.3.2, the treatment of PET filaments with hot aqueous

NaOH solution hydrolyses and dissolves the filament surface, reducing the filament

diameter. Copolymers of PET hydrolyse more rapidly, but the reaction of the

homopolymer can be catalysed with cationic auxiliary products. The resulting fabrics

of denier-reduced PET have a warm silky handle with increased scroop (the

attractive sound that silk fabric gives when it is compressed and released). In Japan,

where this technique has been most popular, weight losses of as high as 40–50% are

not uncommon, but are in the range 10–20% in other countries.

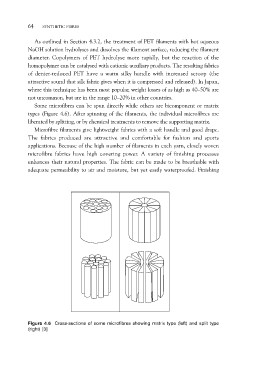

Some microfibres can be spun directly while others are bicomponent or matrix

types (Figure 4.6). After spinning of the filaments, the individual microfibres are

liberated by splitting, or by chemical treatments to remove the supporting matrix.

Microfibre filaments give lightweight fabrics with a soft handle and good drape.

The fabrics produced are attractive and comfortable for fashion and sports

applications. Because of the high number of filaments in each yarn, closely woven

microfibre fabrics have high covering power. A variety of finishing processes

enhances their natural properties. The fabric can be made to be breathable with

adequate permeability to air and moisture, but yet easily waterproofed. Finishing

Figure 4.6 Cross-sections of some microfibres showing matrix type (left) and split type

(right) [3]