Page 64 - E BOOK ENGINE MECHANICAL M2

P. 64

4. SERVICE POINTS OF 4D56 ENGINE COMPONENT

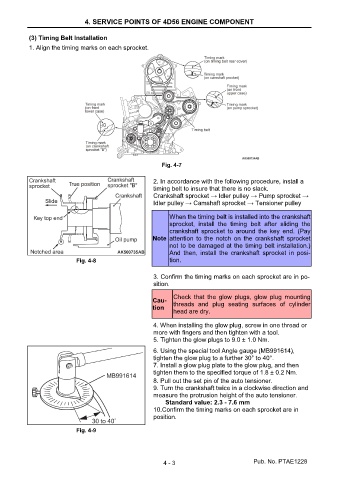

(3) Timing Belt Installation

1. Align the timing marks on each sprocket.

Fig. 4-7

2. In accordance with the following procedure, install a

timing belt to insure that there is no slack.

Crankshaft sprocket → Idler pulley → Pump sprocket →

Idler pulley → Camshaft sprocket → Tensioner pulley

When the timing belt is installed into the crankshaft

sprocket, install the timing belt after sliding the

crankshaft sprocket to around the key end. (Pay

Note attention to the notch on the crankshaft sprocket

not to be damaged at the timing belt installation.)

And then, install the crankshaft sprocket in posi-

Fig. 4-8 tion.

3. Confirm the timing marks on each sprocket are in po-

sition.

Check that the glow plugs, glow plug mounting

Cau- threads and plug seating surfaces of cylinder

tion

head are dry.

4. When installing the glow plug, screw in one thread or

more with fingers and then tighten with a tool.

5. Tighten the glow plugs to 9.0 ± 1.0 Nm.

6. Using the special tool Angle gauge (MB991614),

tighten the glow plug to a further 30° to 40°.

7. Install a glow plug plate to the glow plug, and then

tighten them to the specified torque of 1.8 ± 0.2 Nm.

8. Pull out the set pin of the auto tensioner.

9. Turn the crankshaft twice in a clockwise direction and

measure the protrusion height of the auto tensioner.

Standard value: 2.3 - 7.6 mm

10.Confirm the timing marks on each sprocket are in

position.

Fig. 4-9

4 - 3 Pub. No. PTAE1228